Featured

Guide: Sustainable Fuels Outlook

View the Guide: PAC – Sustainable Fuels Guide ⟶ PAC’s Sustainable Fuels Outlook: Exploring the Future of Renewable Energy PAC’s Sustainable Fuels Outlook provides...

Read More

Sort By

Webinar: The Progress of SAF in South East Asia and Associated PAC Solutions

Watch Now | Renewables Webinar Series: Go Green with PAC

Read More

PAC Overview Brochure

Discover PAC’s comprehensive portfolio of solutions designed to elevate your laboratory operations, streamline process workflows, and deliver powerful digital insights. Download the full overview now...

Read More

Webinar: Renewable Fuels in South East Asia – Bioethanol, FAME & HVO

Watch Now | Renewables Webinar Series: Go Green with PAC

Read More

Webinar: Introduction to the Global Biofuels Standardization

Watch Now | Renewables Webinar Series: Go Green with PAC

Read More

Webinar: Maximizing Efficiency and Uptime: Smart Waste-to-Feedstock Solutions for Fuel & Petrochemicals

Watch Now | Renewables Webinar Series: Go Green with PAC

Read More

Webinar: The Current and Future Biofuel Trends in South East Asia

Watch Now | Renewables Webinar Series: Go Green with PAC

Read More

Webinar: Leak Testing Decoded: Essential Fundamentals and Concepts for Delivering Quality

Watch Now | Leak Testing Decoded: Essential Fundamentals and Concepts

Read More

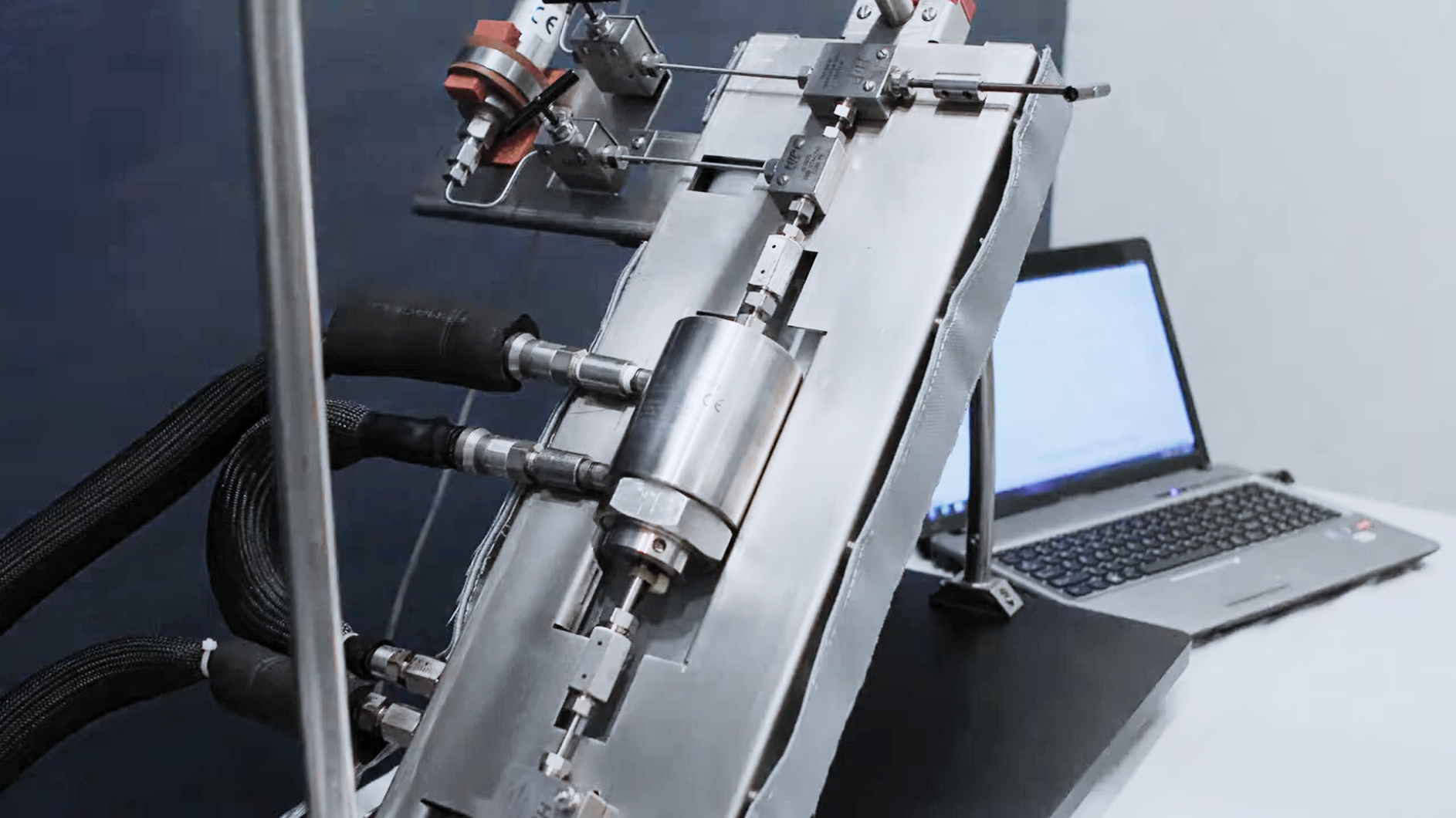

Maximizing Efficiency and Accuracy in Refinery Blending

This case study explores how the MicroDist analyzer helps refineries reduce product giveaway and maximize profitability

Read More

Guide: Sustainable Fuels Outlook

View the Guide: PAC – Sustainable Fuels Guide ⟶ PAC’s Sustainable Fuels Outlook: Exploring the Future of Renewable Energy PAC’s Sustainable Fuels Outlook provides...

Read More

The Relationship Between Pressure Decay & Leak Rate

By default, pressure decay panels measure change in pressure to indicate the presence of a leak in a pressurized test piece e.g., mbar, Pascal, mbar/sec...

Read More

Ensuring Quality & Performance in Wearable Medical Technology: Innovative Non-Destructive Testing Methods for IP67 Products

In modern healthcare, wearable technology has emerged as a revolutionary force, ushering in a new era of personalized and proactive health management. With such technology,...

Read More

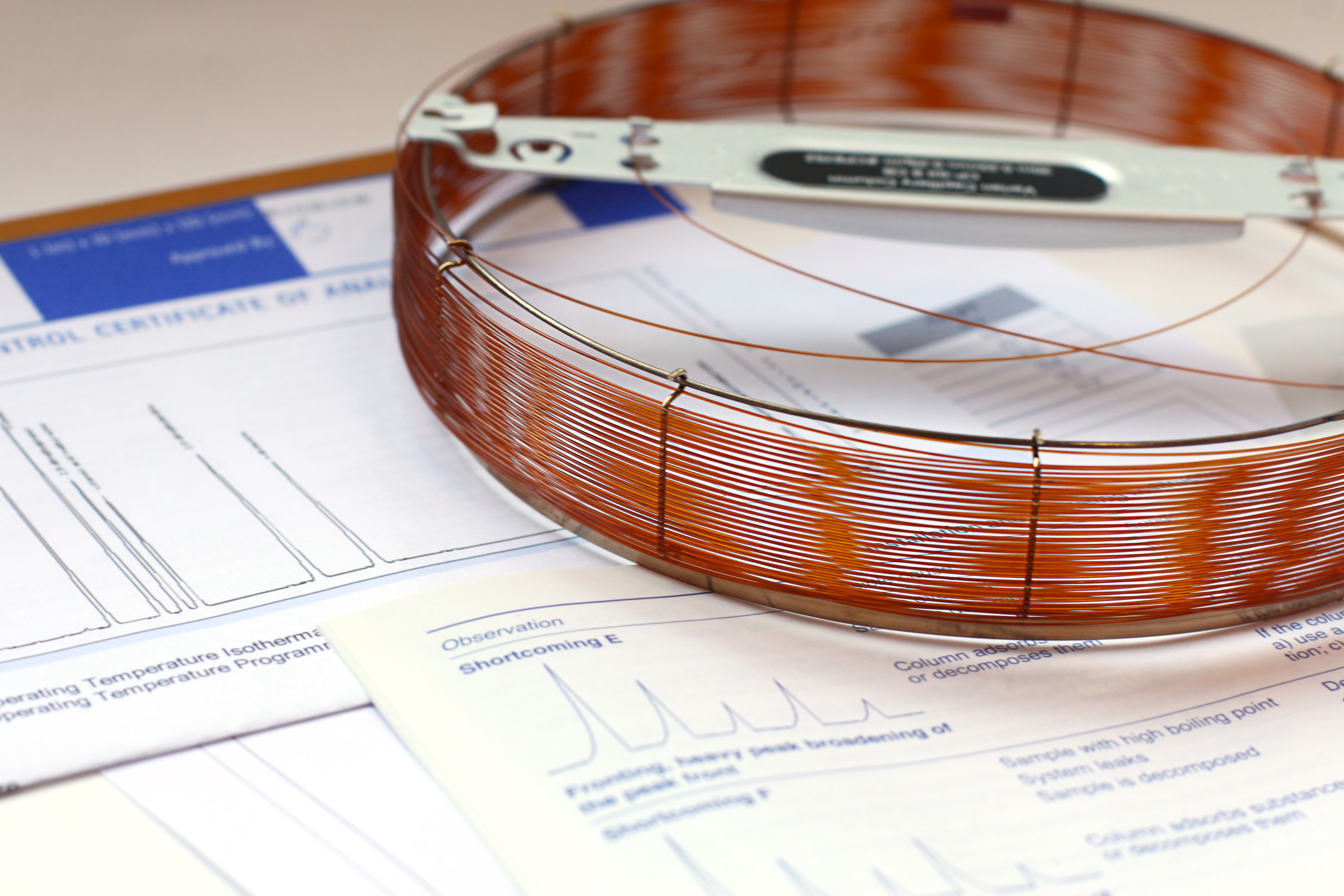

Enhancing Fuel Quality with Gas Chromatography

Gas chromatography (GC) is a vital tool for separating and analyzing compounds that can be vaporized without decomposition.

Read More

Transforming the Industry with PACe Digital Ecosystem

Transforming the Industry with PACe Digital Ecosystem.

Read More

The Circular Economy as An Emerging Marketing in the Petrochemicals Industry

Download the Article ⟶ Transforming Petrochemicals: Market Trends, Circular Economy, and PAC Solutions The petrochemical industry is undergoing a significant transformation, shifting focus from traditional...

Read More

GCxGC Isn’t Just a Tool for Research

How ASTM D8396 is shaping the future of compositional characterization in synthetic aviation fuels (SAF).

Read More

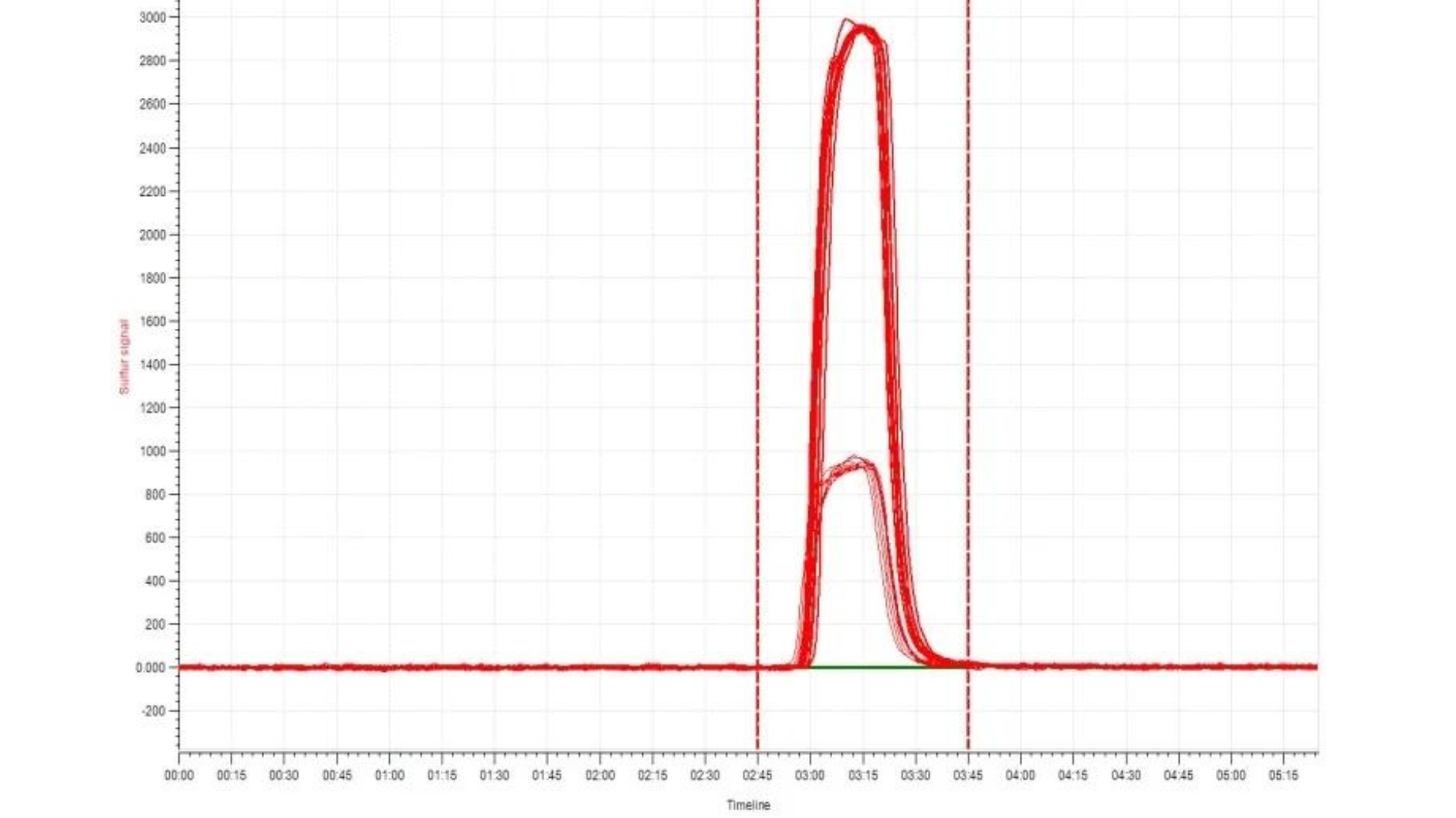

Determination of Total Sulfur by UVF According to ASTM D5453

Sulfur is a natural present element in nearly all hydrocarbon feed streams and responsible for numerous unwanted effects such as detrimental product quality, catalyst poisoning...

Read More

Using Gas Chromatography for the Analysis of Ultra Low Sulfur Compounds in Gaseous Fuels

Using Gas Chromatography for the Analysis of Ultra Low Sulfur Compounds in Gaseous Fuels Robust solution utilizing AC SeNse detector Ultra-low detection limits Superior sensitivity,...

Read More

Alternative Options for Distillation of Gasoline at Atmospheric Pressure

A number of refineries utilize a combination of technologies to effectively measure and enhance the distillation of crude oil into isolated hydrocarbon components, in order...

Read More

Total Sulfur and Nitrogen Analysis in Biofuels

Bio-feedstocks present a viable alternative to crude oil for the production of fuels. As with conventional fuels, these biofuels need to comply with the most...

Read More

Determination of Total Sulfur in Light Hydrocarbons by UVF

Sulfur is a natural element present in most hydrocarbon feed streams and contributes to a number of undesirable effects, including detrimental product quality, catalyst poisoning...

Read More

The Regulation of Gasoline Requires Thorough Analysis

Gasoline is primarily used as an engine fuel for vehicles, and as a product that is sold on the retail market, it must meet specific...

Read More

Exploring JFA-70Xi as a Sustainable Aviation Fuel

SAF (sustainable aviation fuels, sometimes referred to as renewable jet fuels or biojets) have widely been accepted as the major contributor to the aviation industry’s...

Read More

The Emergence of the Circular Economy as a New Market in the Petrochemical Sector for WPPO

In the energy industry, oil and gas continue to maintain a position of prominence, but the sector is currently undergoing a transition, changing its focus...

Read More

How does OptiFuel Enhance the Analysis of Gasoline, Diesel, and Renewables?

Global oil demand is on the rise, driven strongly by the petrochemical and aviation sectors.1 However, the availability of traditional energy sources, in particular crude...

Read MoreWhat is the Future of Viscosity Testing?

Viscosity testing is one of the foundations of performance assessment and quality control in the petroleum and lubricants sectors.

Read More

Enhancing the Blending and Measurement of SAF and Jet A Fuels with Icon Scientific & PAC Process Analyzers

Enhancing the Blending and Measurement of SAF and Jet A Fuels with Icon Scientific by PAC Analyzers.

Read MoreIcon Peltier Vacuum Chamber

Icon’s new technology blog, focusing on the industry-changing innovations integrated into our word-leading range of physical property analysers.

Read More

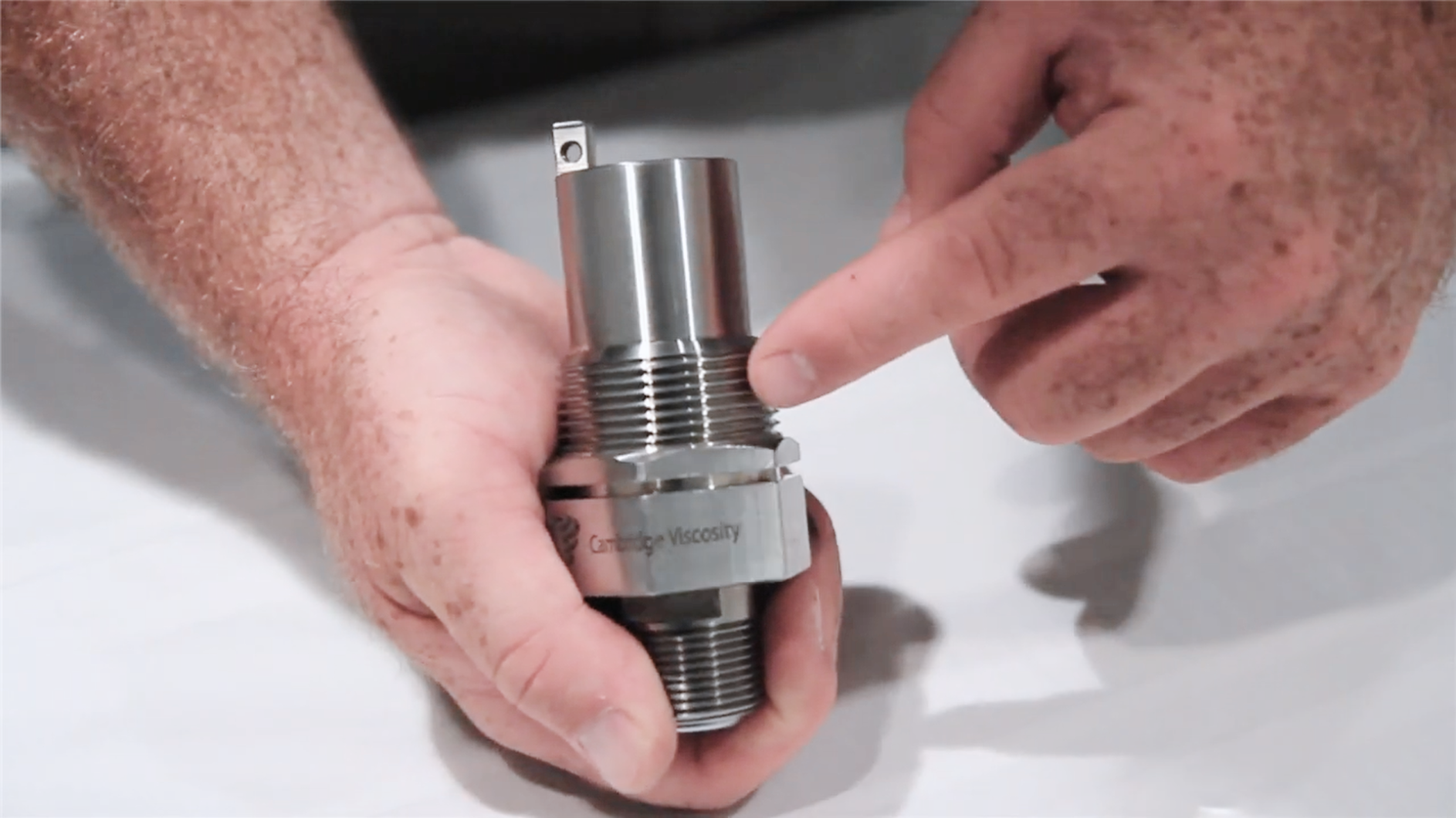

Measuring Viscosity: In-Line and In-Tank Viscometers

Learn about in-line and in-tank process viscosity sensors from Cambridge Viscosity by PAC.

Read More

Viscosity Control Improves the Medical Device Manufacturing Process

When choosing a viscometer, it’s important to know your application specification and which questions to ask.

Read More

How to Choose a Viscometer

When choosing a viscometer, it’s important to know your application specification and which questions to ask.

Read MoreIcon’s Innovations: Advanced Cryo-Cooling Technology

Icon’s advanced Cryo-Cooling Technology: Innovation that is Rocket Science.

Read More

Monitoring Sulfur and Nitrogen in High-Viscous Products

Monitoring of products such as diesel or gasoline is common, and there are many options in the marketplace for measurement of liquid products with low...

Read More

Determination of Total Sulfur in Light Hydrocarbons by UVF according to ASTM D5453

The ElemeNtS analyzer offers rapid and accurate determination of chemically bound sulfur, a fully automated injection and combustion system, and excellent sensitivity, repeatability, and linearity.

Read More

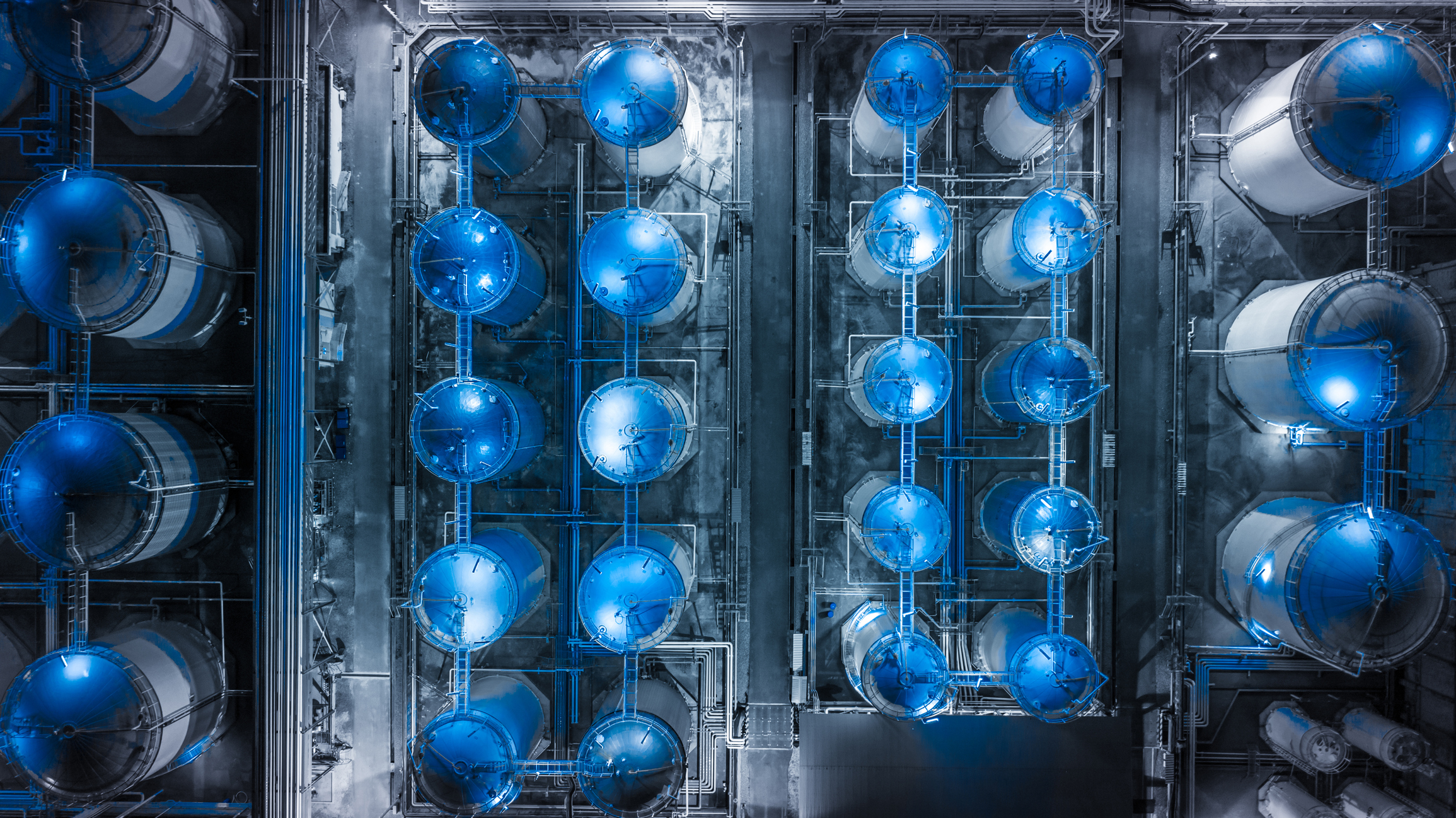

Thermal Oil Recovery

Thermal oil recovery is anything that uses steam to enhance oil recovery, or to recover hydrocarbons that are below the ground. This is common, for...

Read More

Reservoir Management: Online Oil-in-Water Monitoring

Overview of Advanced Sensors Oil-in-Water Units by Chevron.

Read More

Petroleum Institute Mexico Uses SIMDIS Technology to Accurately Determine TBP Physical Distillation

Read MoreIcon Scientific: Bigger, Better, and Greener

As we enter the final months of 2023, Icon Scientific is looking back on another year of innovation and growth.

Read More

The Regulation of Gasoline Requires Thorough Analysis

Gasoline is primarily used as an engine fuel for vehicles, and as a product that is sold on the retail market, it must meet specific...

Read MoreBe The First To Know

Stay up to date with PAC news & updates, delivered directly to your inbox.