The petrochemical industry is experiencing an important transition fueled by:

The Benefits of PAC Petrochemical Solutions

Circular Economy

Read more for plastic circularity.

Integrated Refineries

Read more for primary building blocks.

Emerging Feedstocks

Read more for emerging feedstocks.

Chemical Conversions

Read more for chemical conversions.

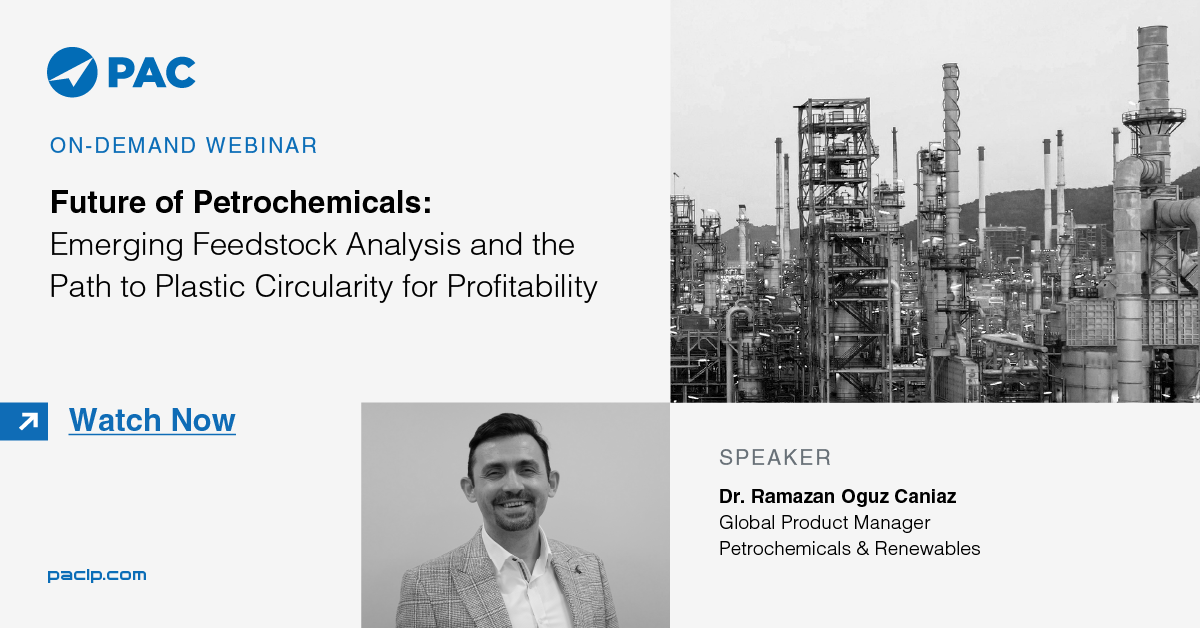

On Demand Webinar

Increasing Your Profitability in the Petrochemicals Market through State-of-the-Art Laboratory & Online Measurements

Can sustainability and profitability go hand in hand? Watch PAC's on-demand webinar that explores how advanced analytical measurement techniques can drive both growth and resilience in the petrochemical industry. With expertise in distillation, elemental analysis, and gas chromatography, PAC offers innovative solutions to optimize operations for players in plastic circularity.

Watch WebinarFeatured Solutions for Petrochemicals

SeNSe²

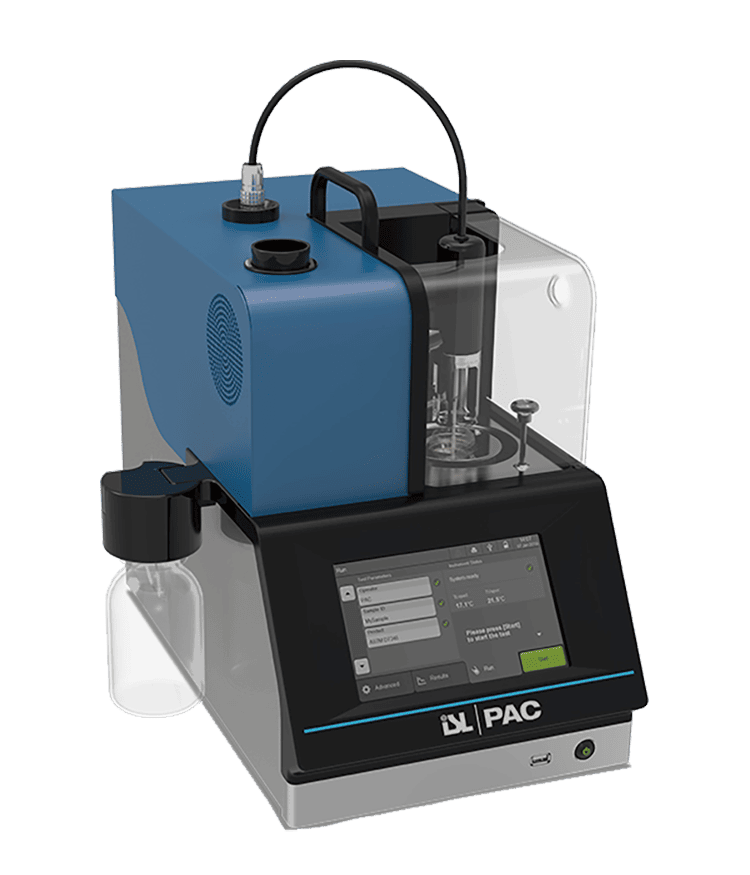

OptiDist 2

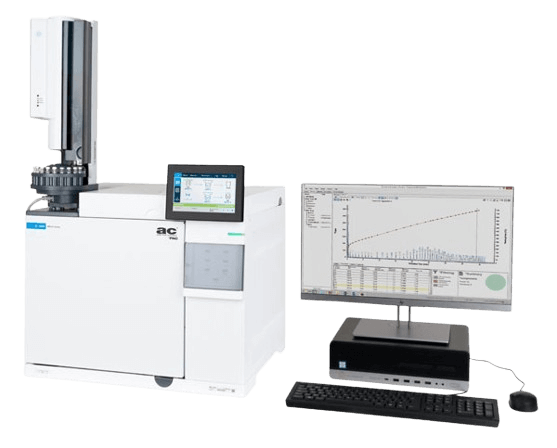

Customized GC

NSure

OptiPMD