PAC Ensures Proof of Compliance for Aviation Fuels

The aviation industry is under increasing pressure to adopt sustainable practices and reduce its environmental footprint. Sustainable Aviation Fuel (SAF) presents a promising solution, with the potential to significantly reduce CO2 emissions and transition towards a greener future. PAC's expertise in analytical solutions ensures that SAF meets stringent industry standards and paves the way for sustainable aviation practices worldwide.

PAC helps customers in the renewable fuel industry

Increase Operational Capacity

Maximize Production

Reduce

Variability

Maximize Percentage

Yield

Reduce

Downtime

Contain Operational Expenses

Podcast | Gordon Chiu on the World’s Transition to Renewable Energy

Tune in to listen to Gordon Chiu, PAC’s Product Manager for Renewable Fuels, explain how the world is moving towards renewable energy and away from fossil fuels and how PAC is positioning itself during this time of energy transition.

Explore PAC Solutions for Sustainable Aviation Fuel

OptiDist 2

JFTOT® IV

OptiReader

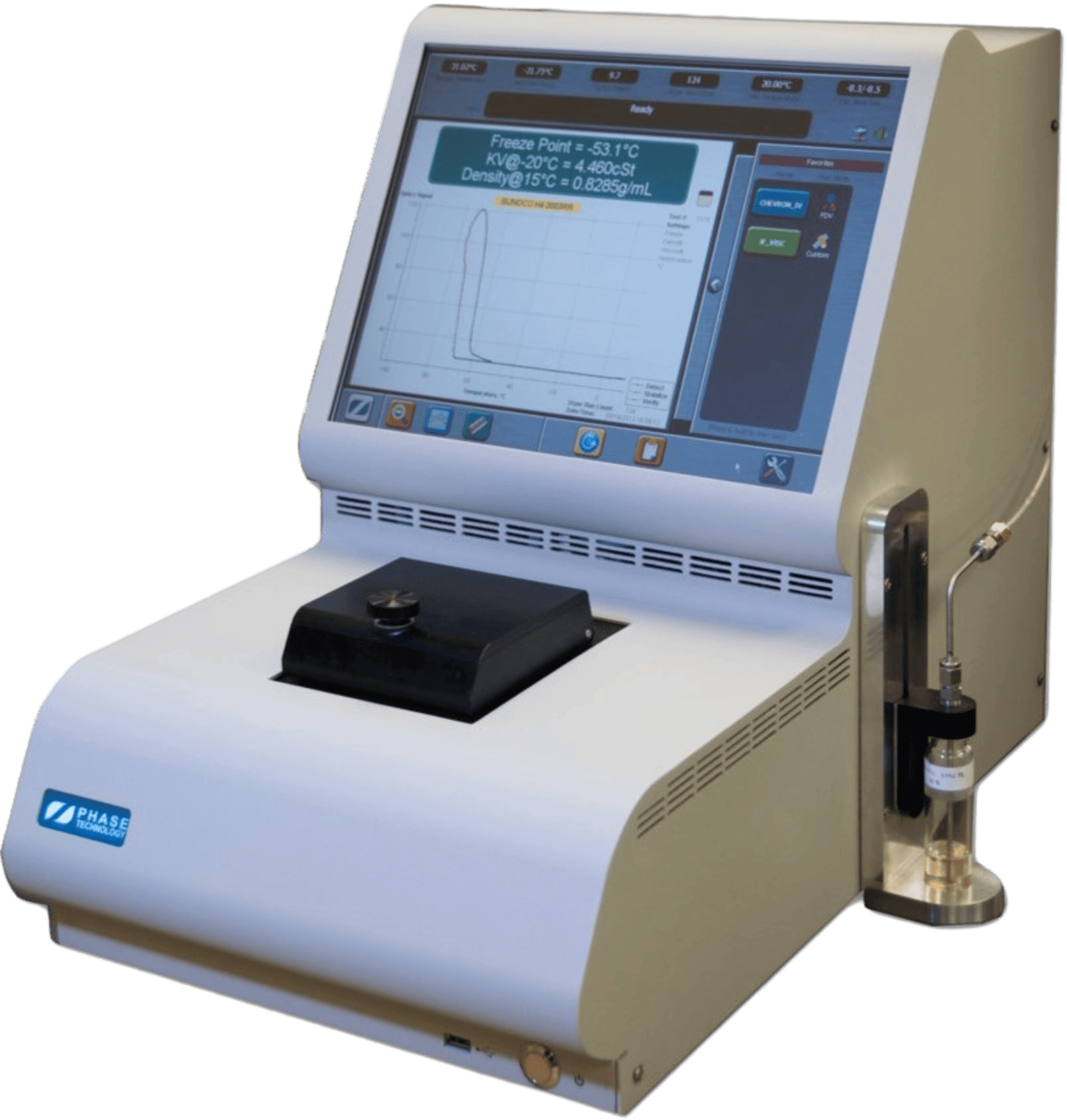

JFA-70Xi

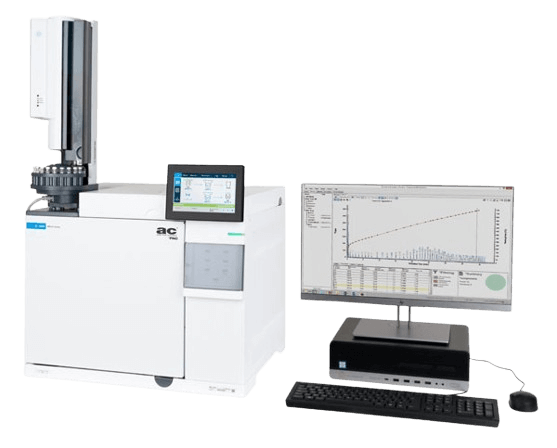

Customized GC