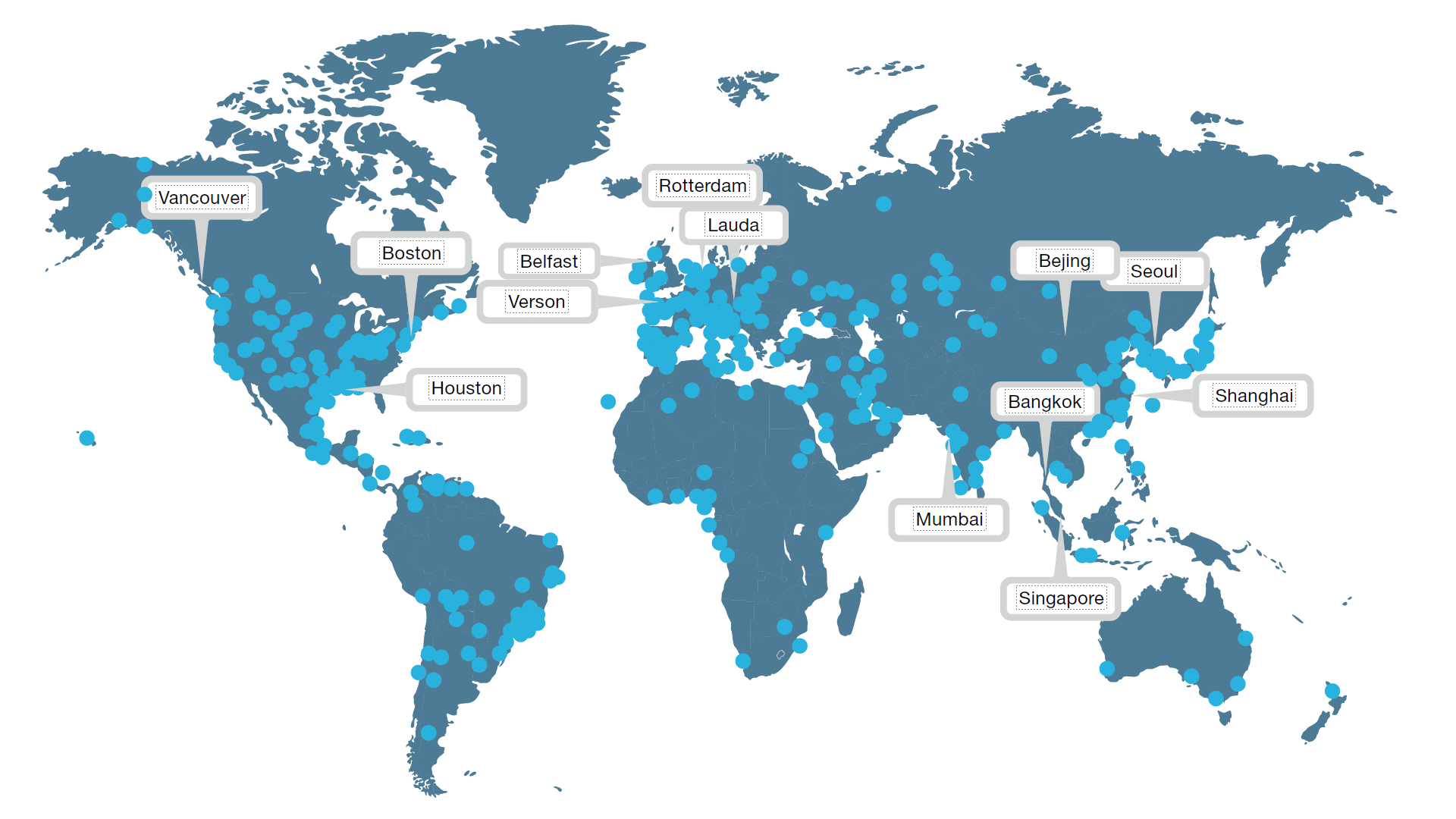

A Track Record of Success Across the Globe

PAC maintains a strong global presence, with 13 offices around the work, plus a network of 140 distributors, to provide excellent service and support to our customers.

We have an installed base of hundreds of thousands of instruments located across six continents.

Process

Biodiesel is produced through a process called transesterification, where FAME is formed from the triglyceride (plant or animal oils) by reacting with methanol in the presence of a catalyst. This process causes a separation of two distinct layers—glycerine and crude biodiesel. The glycerine is removed, and the crude biodiesel is then washed and purified, while the alcohol can be recovered and reused.

During this process, just as in the processing of fossil fuels and eventual blending, biofuels must meet a number of specifications, including ASTM D6751 or EN 14214. PAC’s analyzers are the industry standard for monitoring fuel properties. Our analyzers determine FAME content, free and total glycerine, viscosity, cetane number, cloud point, and other properties.

Managing Feedstock

When it comes to renewable fuel sources, the feedstock is widely varied. However, the limited amount of available feedstock, as well as the controversy around feedstock being used for fuel rather than to abate global food scarcity contributes to low production as a result of feedstock availability.

PAC helps biofuel producers optimize operating parameters to maximize percentage yield.

Operating Amidst Uncertainty

As the price of crude oil increases, biofuels become more economically feasible. However, the price of oil is heavily impacted by economic and geopolitical events, making it volatile and hard to forecast. This makes it hard to predict long-term demand for biofuels.

PAC helps biofuel producers reduce product variability and ensure uptime and maximize profitability.

Managing Feedstock

When it comes to renewable fuel sources, the feedstock is widely varied. However, the limited amount of available feedstock, as well as the controversy around feedstock being used for fuel rather than to abate global food scarcity contributes to low production as a result of feedstock availability.

PAC helps biofuel producers optimize operating parameters to maximize percentage yield.

Operating Amidst Uncertainty

As the price of crude oil increases, biofuels become more economically feasible. However, the price of oil is heavily impacted by economic and geopolitical events, making it volatile and hard to forecast. This makes it hard to predict long-term demand for biofuels.

PAC helps biofuel producers reduce product variability and ensure uptime and maximize profitability.

World-Class Products & Solutions

|

|

Includes enhanced safety features and simplified operational capabilities through accurate and reliable jet fuel analysis, with a small-footprint design.

|

|

Offers accurate and fast results through an Ellipsometric jet fuel thermal oxidation heater tube scanner, with excellent data integration capabilities.

|

|

Performs freeze point, density, and viscosity in one self-cleaning unit. Features a new, side loaded automatic sample injection port.

|

|

Incorporates high-performance liquid chromatography (HPLC) technology to detect aromatics in jet fuel in the 150ºC to 400ºC (752ºF) range within 25 minutes.

|

|

Detects Total Sulfur and/or Total Nitrogen efficiently using ultraviolet fluorescence (UVF) and chemiluminescence (CLD) in solid, liquid, gaseous materials and LPG samples.

|

|

Measures FAME (biodiesel) in jet fuel and features a unique combination of Deans switching. This gas chromatography application includes a re-focus module that eliminates the need for cryogenics.

|

|

Provides enhanced, detailed and reliable compositional information on jet fuel streams.

|

|

Combines the capabilities of GS PPA, TD PPA and QuickSpec into one instrument to determine the concentration content of wide varieties of FAME in diesel fuel.

|

|

Determines the quality of FAME blending stock for diesel fuel, and yields fast results from a single dedicated system.

|

|

Provides the best precision in the market for determining the Derived Cetane Number of all types of diesel fuel, biodiesel, FAME, HVO, BTL, and GTL.

|

|

Performs four diesel fuel tests in one single unit—cloud point, pour point, viscosity and density, and does it all in less than 25 minutes. (The only instrument in the world to do this.)

|

|

Detects flashpoint accurately up to 400°C for petroleum products, biodiesels, solvents, chemicals, fluxed bitumen, and food and beverages.

|

|

Offers precision and ease of use in a state-of-the-art solution for performing atmospheric distillation.

|

|

Determines the boiling range characteristics of fuel products in less than 10 minutes, using only 10 ml of sample.

|

|

Performs pour and/cloud point testing of any petroleum products, down to -95°C (-139°F), in accordance with all international standards.

|

|

Provides highly accurate cloud and pour point temperatures of petroleum products during cooling.

|

|

Determines the boiling range characteristics of various commercially available fuel products, light and middle distillates, on process streams quickly and accurately.

|

|

Offers a complete range of simulated distillation analysis solutions up to 120°C.

|

|

Delivers fast, group-type analysis of gasoline and gasoline blend streams using multi-dimensional gas chromatography.

|

|

Allows the AC Analytical Controls gas chromatograph to be customized to fit your specific analysis requirements.

|

Global Strategies for Renewable Fuel Sources

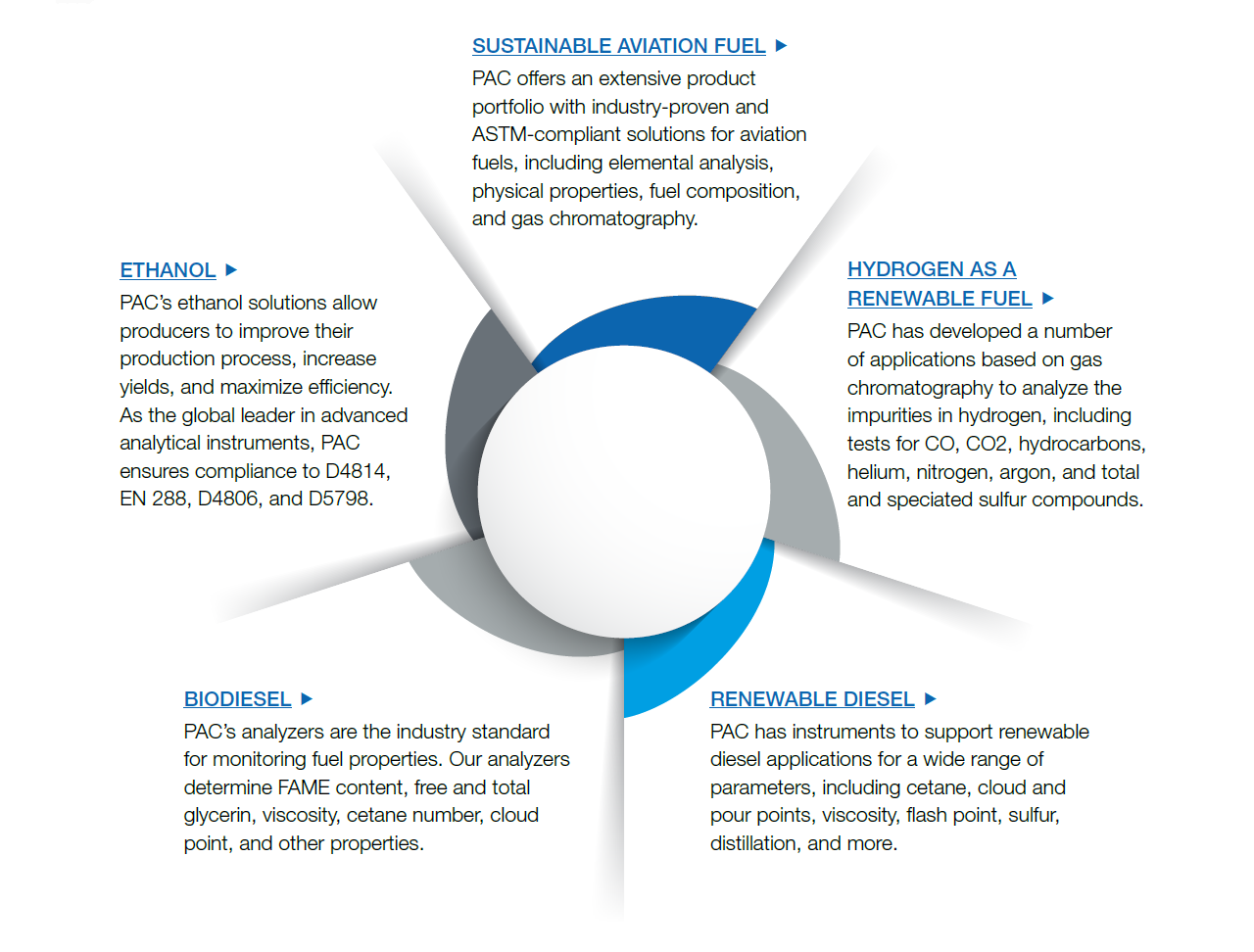

The demand for renewable fuels is increasing, as nations around the world recognize the impact of fossil fuels on climate change and greenhouse gas emissions. Transport sectors, including aviation, heavy-duty and light-duty vehicles, and even marine, have invested in equipment and technologies that accommodate renewable fuels. These include sustainable aviation fuel (SAF), renewable diesel (HOV), biodiesel, and ethanol. Some are even considering hydrogen as a renewable fuel.

Service & Support

PAC offers service and support options to ensure the performance, reliability, and longevity of our products. Whether you require preventative maintenance, calibration and startup, or emergency services, PAC’s team of expert technicians will keep your equipment running at optimum levels.

Repair & Maintenance

PAC offers individual services for preventative maintenance, calibration, and relocation services. All our service repair facilities have the technology and know-how necessary to inspect, repair and calibrate your PAC equipment. All work is performed by our factory trained and certified technicians who use only approved spare parts to guarantee your instrument performance.

Field Services

Our on-site customer services include installation and commissioning of equipment, as well as emergency site visits. All services are performed by experienced, qualified PAC service representatives who have successfully completed PAC’s rigorous training and certification program.

Total Care Service Programs

We have two service programs to fit the unique needs of our customers.

Features & Benefits

|

Basic Care

|

Complete Care

|

| Priority response/repair |

|

|

| Pre-scheduled PM & Performance Verification Certificate |

1 Visit |

1 Visit

|

| Onsite PM Travel Cost |

1 Visit

|

1 Visit

|

| Repair Parts Cost |

|

Unlimited

|

| Repair Travel Cost |

|

Unlimited

|

| Customer training |

10% discount |

10% discount

|

| Hardware/software updates |

|

As needed

|

ABOUT PAC.

PAC develops advanced instrumentation for lab and process applications based on strong Analytical Expertise that ensures Optimal Performance for our clients. Our analyzers help our clients meet complex industry challenges by providing a low cost of ownership, safe operation, high performance with fast, accurate, and actionable results, high uptime through reliable instrumentation, and compliance with standard methods.

Our solutions are from industry-leading brands: AC Analytical Controls, Advanced Sensors, Alcor, Antek, Herzog, ISL, Cambridge Viscosity, PSPI, PetroSpec, and Phase Technology. We are committed to delivering superior and local customer service worldwide with 16 office locations and a network of over 50 distributors. PAC operates as a unit of Roper Technologies, Inc, a diversified technology company and a constituent of S&P 500, Fortune 1000, and Russell 1000 indices.

Renewable Fuel Solutions

Please contact PAC for more information and detailed discussion