PAC Solutions Enhance Your Ethanol Production Efficiency and Compliance

PAC supports our customers in ethanol production with precise measurement and analysis capabilities. Our analyzers ensure accuracy in distillation, ethanol concentration, sulfur analysis, hydrocarbon monitoring, and flashpoint determination, ensuring adherence to industry standards and environmental regulations. Leveraging industry-leading solutions like MicroDist, OptiDist, SIMDIS, and OptiFuel, we offer comprehensive insights into ethanol characteristics. PAC’s innovative Icon Scientific ethanol blending system, featuring patented precision-engineered piston cylinders, delivers unparalleled accuracy in blending gasoline and ethanol.

With the projected increase in ethanol demand over the next 15 years, PAC’s analyzers play a vital role in enhancing production processes, increasing yields, and maximizing efficiency. As the global leader in advanced analytical instruments, PAC ensures compliance with standards like D4814, EN 288, D4806, and D5798, delivering highly accurate results, using minimal sample volumes, and conducting analyses swiftly.

PAC helps customers in the renewable fuel industry

Increase

Operational

Capacity

Maximize

Production

Reduce

Variability

Maximize

Percentage

Yield

Reduce

Downtime

Contain

Operational

Expenses

Podcast | Gordon Chiu on the World’s Transition to Renewable Energy

Tune in to listen to Gordon Chiu, PAC’s Product Manager for Renewable Fuels, explain how the world is moving towards renewable energy and away from fossil fuels and how PAC is positioning itself during this time of energy transition.

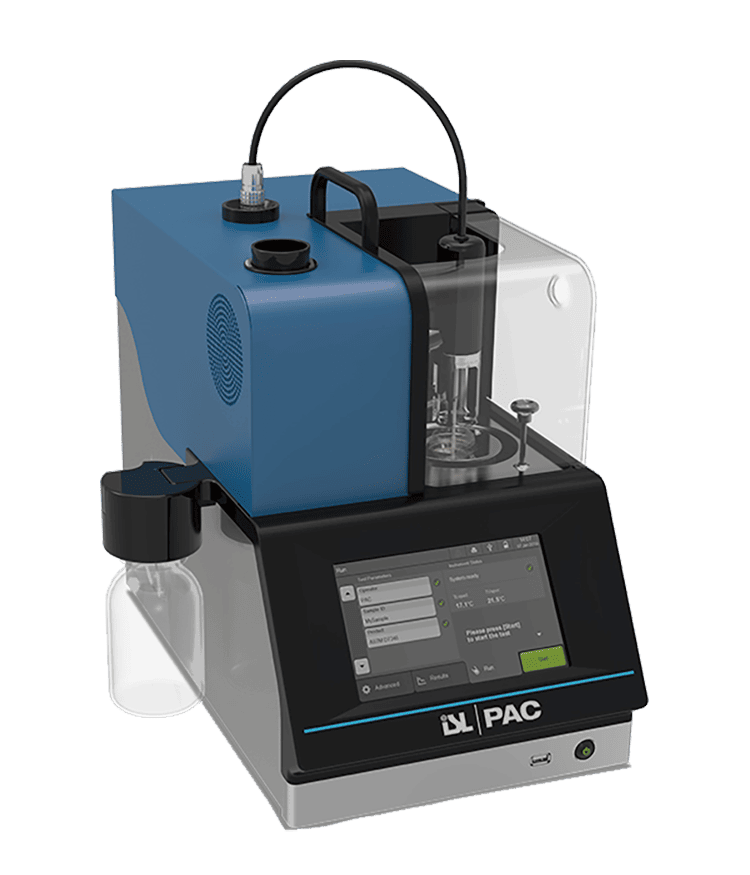

PAC Solutions for Ethanol

MicroDist

Reformulyzer M4

SIMDIS Analyzer

Customized GC

OptiDist 2

OptiPMD

OptiFlash Pensky Martens