State-of-the-Art Solution

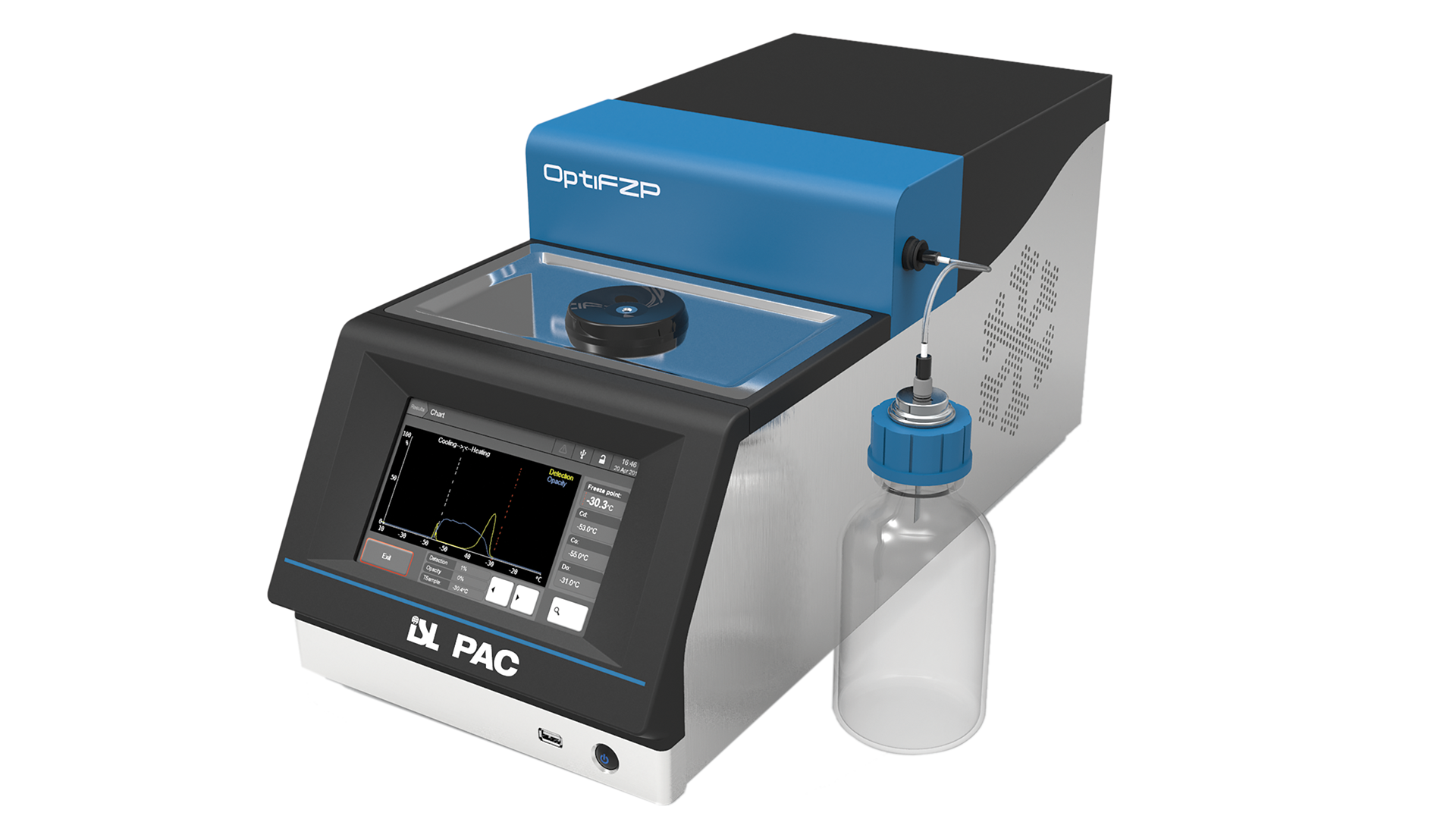

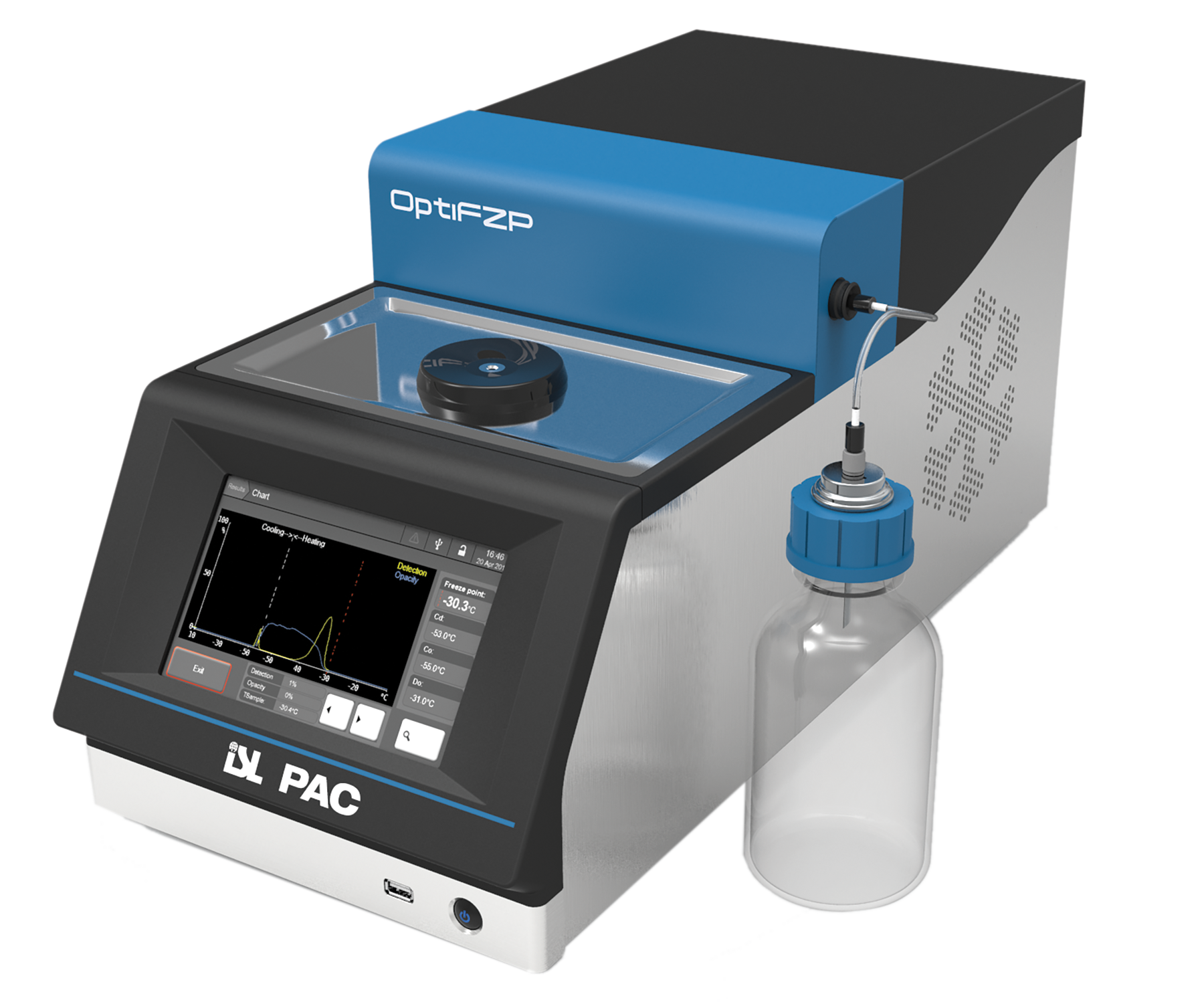

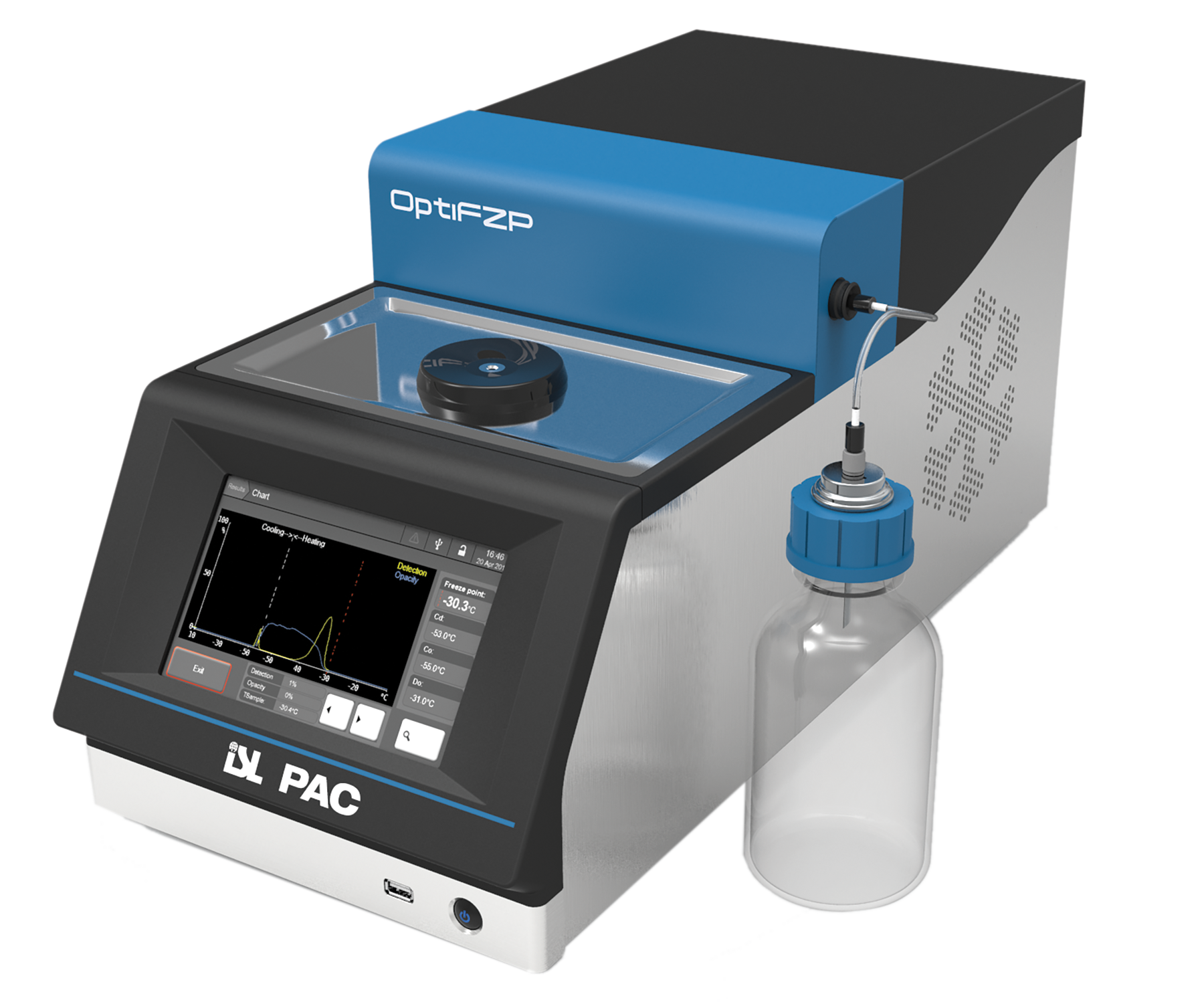

Designed to increase the laboratory productivity through automation, the ISL OptiFZP precisely measures the Freezing Point of jet fuels completely unattended, therefore reducing the operator time but also improving greatly the analysis performance.

Product Overview

The next generation Freeze Point Analyzer offers proven technology used by labs worldwide. The powerful internal cooling system can measure up to -100C (-148F) without the need of an external cooling bath. The unique patented detection cell provides ultra-high accuracy with unmatched precision, while maintaining its compact footprint. The newly designed OptiFZP includes a color touchscreen and advanced electronics that allows network printing and electronic data transfer from the analyzer to a PC.

Proven to provide highly precise measurements, OptiFZP’s ASTM D7153 method is an approved freezing point test method in all of ASTM D1655, ASTM D7566 and Def Stan 91-091 global jet fuel specifications for testing all types of jet fuels, including sustainable aviation fuels (SAF).

Key Features

Freeze Point Measuring Range down to -100°C

Fast and Accurate Freezing Point Determination in 15 Minutes

Superior correlation with manual method on contaminated samples

Compact Design with Built-in Cooling System

Self-Cleaning operation, no cleaning required

Built in QC-Chart for trend monitoring

Improved Productivity and Ease of Use With a New Touch-Screen and Advanced Electronics

One-button push operation

Specs

Test Methods & Precision

Standard Test Methods:

ASTM D7153 (IP 529), ASTM D2386 (IP 16), ISO 3013, JIS K2276 equivalent or better

Repeatability: 0.6 ºC

Reproducibility: 0.9 ºC

Performance

Detection: Optical detection (patented)

Cooling System: Internal Stirling Cooling

Measuring Range: Ambient down to -100⁰C (-148°F) , ⁰C or ⁰F configurable

Operation

Operator Time: ½ minute per test

Test Duration: 15 minutes

Sample Volume: 10 ml, including volume for cleaning

Sample Injection: Disposable 10 or 20 ml syringe

Cleaning: Self-cleaning operation, no cleaning required

Calibration: Automatic calibration routine for temperature measurement

5 correction points

Programmable calibration frequency

Calibration ticket printing

Documentation

Display: Screen size 7” (16/9) with resolution (800×480); resistive touchscreen with real time graphic display

Printing: Detailed detection curve tracking of fuel behaviors during the test; can be printed as part of test report.

Detailed test report in °C or °K with date & time stamped, sample information, test conditions, apparatus serial number

Result Documentation: 200 test runs (results) and 40 products (with cooling profiles)

QC-Functions: Automatic QC-sample handling and QC-Chart

Interface

User Interface: 7” color touch-screen, alpha-numeric data input, barcode reader

Languages: English, French, others on request

Printer: The list of compatible printers that are proven to work successfully are as follows:

By USB: Brother HL-3170 CDW, Lexmark CS 310, Ricoh SP C250N, HP OfficeJet Pro 8120, Brother HL-L5000D

By Ethernet: Ricoh Aficio SG 3110dn, HP Color LaserJet Pro M425dn

LIMS interface: Ethernet or RS232, Used defined Data String, Automatic LIMS transfer

Data Export: USB Memory Stick, Import into Excel

Password Protection: Different Access levels for Operator, Service or Lab Manager

Calibration & Diagnostics:

User defined Calibration Intervals

Automatic Diagnostic functions

Accessories: Barcode Reader, Printer, Calibration Probe

Utility Requirements

Electrical: 90V to 240VAC ±10% switchable; 50-60Hz ; 300W

Ambient Conditions: Temperature: max. 10° to 35°C; recommended 15° to 25°C

Humidity: 80% rel. at 35°C

Storage temperature: -15 to +55°C

Dimensions: 25 cm (10”) wide, 60 cm (24”) deep, 27 cm (11”) tall

Weight: 29kg, (64 lb)