Transforming the Industry with PACe Digital Ecosystem

Transforming the Industry with PACe Digital Ecosystem.

In process operations, where unbeatable uptime leading to maximum throughput is the goal, PAC offers PACe digital ecosystem, a powerful architecture designed to link PAC instruments across multiple sites and geographical locations to support asset management, deliver instrument insights, and monitor predictive analytics. PAC is a leading global manufacturer of advanced analytical instruments for laboratories and online process applications. With a wide portfolio of analytical instrumentation, and 10,000+ instruments in the field, PAC is well positioned to extreme value to customers with digital solutions like PACe.

Driving Operational Excellence Through Insight and Predictive Intelligence

PACe acts as a hub of global, instrument, standards, and service knowledge, bringing all available instrument data and ensuring its accessibility. By empowering processes with actionable insights to optimize operational efficiency and minimize downtime, PACe unlocks unprecedented levels of productivity and performance. PACe consists of three main functional areas: 1) Asset Management, 2) Instrument Insights, and 3) Predictive Analytics.

Asset Management: Optimizing Operations

PACe’s asset management capabilities redefine how refineries manage their operations. By providing a comprehensive visualization of assets and forecasting usage patterns, PACe enables refineries to optimize product margins and throughput. Moreover, PACe facilitates cost calculations, capacity forecasting, and workflow optimization, empowering refineries to streamline operations and enhance profitability.

Instrument Insights: Real-time Understanding

PACe empowers laboratories with real-time visibility into instrument performance and historical logs. Through features such as real-time alerts and comprehensive analytics, PACe enables refineries to proactively identify and mitigate potential issues, thereby minimizing downtime and maximizing operational efficiency.

Predictive Analytics: Anticipating Needs

PACe’s predictive analytics capabilities represent a paradigm shift in process operations. By leveraging machine learning and real-time monitoring, PACe helps to anticipate maintenance needs, optimize uptime, and reduce operational costs. With automatic calculations and root cause analysis, PACe empowers refineries to make data-driven decisions, driving continuous improvement and innovation.

PACe Capabilities

PACe collects the full gamut of instrument logs – from sample measurements, all the way to control parameters of critical parts. This information is used for additional diagnostics and optimized functions, delivering actionable insights through visualizations, statistics, and alert-functions to optimize the functionality of the instrument. PACe is able to summarize the current and future functionality of all instruments, collecting logs and calculations of an unlimited number of laboratories within an organization. It represents a single platform to access the entirety of instrument logs.

One of the defining features of PACe is its ability to seamlessly integrate additional features for single instruments. Labor-intensive calibration processes and fragmented settings adjustments are no longer an accepted part of the process. With PACe, new developments such as calibrations and settings modifications are simplified through a centralized platform, streamlining operations across the laboratory. For instance, implementing a translation function becomes a straightforward task, benefiting not only individual instruments but also enhancing broader functionalities like report generation.

Moreover, PACe changes how routine diagnostics are handled by harnessing both new and historical logs to optimize instrument uptime. From advanced reporting functions to granular visualizations of sensor performance, PACe empowers laboratories to maximize the longevity and efficiency of their instruments. This proactive approach to maintenance ensures uninterrupted workflow and enhances overall productivity.

The flexibility of PACe extends beyond individual instruments, encompassing future trends and innovations in laboratory operations. As technology changes, PACe will continue to evolve, ensuring compatibility with emerging standards such as remote access protocols. By embracing change and adaptability, PACe will keep pace with future advancements, enabling laboratories to stay agile in an ever-evolving landscape.

Understanding PACe

PACe represents a transformative leap forward for the refining industry. By seamlessly integrating analytical instruments into a digital ecosystem, PACe enhances efficiency, reliability, and productivity. With its focus on unbeatable uptime and maximum throughput, PACe ushers in a new era of innovation in digital analytics that delivers quantifiable value to customers. As the refining industry embraces digitalization, PACe leads the way, offering unmatched solutions that meet the evolving needs of the industry.

To learn more about PACe visit info.www.paclp.com/PACe or contact your local PAC distributor to schedule a demo.

PACe

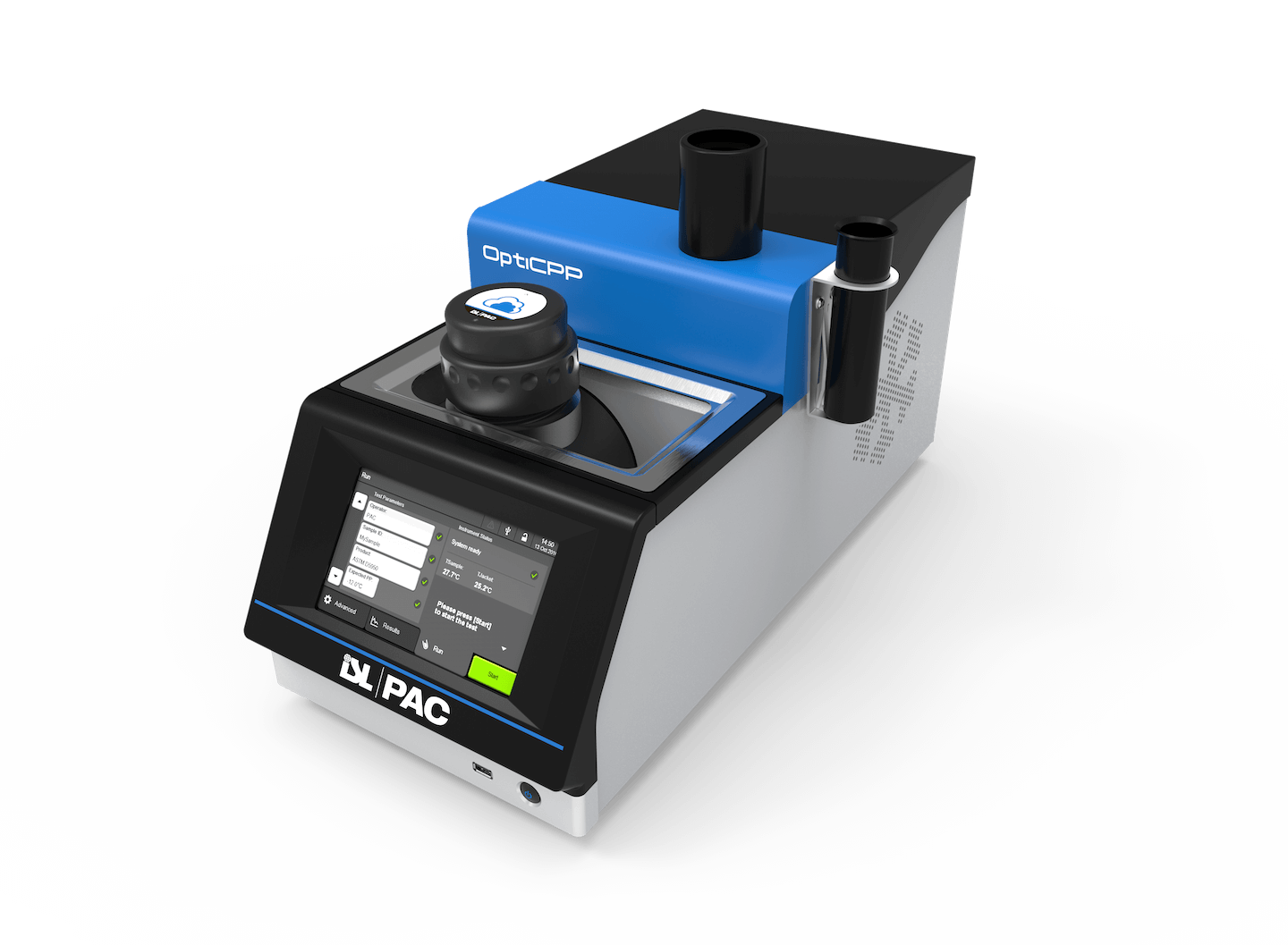

OptiDist 2