Reservoir Management: Online Oil-in-Water Monitoring

Overview of Advanced Sensors Oil-in-Water Units by Chevron.

Background

Older generation online oil-in-water (OiW) monitors may suffer from fouling of optics due to scales, soaps, emulsions, sludge, etc., resulting in inaccurate (usually low) concentrations.

New generation OiW monitors:

- Yield more accurate OiW concentrations

- Improve accuracy of the OiW measurements, allowing operators to optimize water treatment systems so that more product is recovered and less is re-injected or discharged into the environment.

- Reduce operator maintenance and recalibration significantly

- Optimize water treatment systems to limit product losses

- Reduce liability for hydrocarbon discharges into the environment

Challenges

The primary challenge is convincingly conveying that the new monitors out-perform older monitors and are cost-effective investments. The cost of the new monitors is about twice the cost of the older monitors.

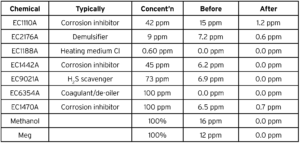

Chemical Interference

Many process chemicals fluoresce, and many fluoresce more than oil. The fluorescence of chemical additives can swamp the fluorescence of oil in certain parts of the optical Spectra, creating a false high ppm reading.

Table 1: Chemical Interference

Chemical Interface

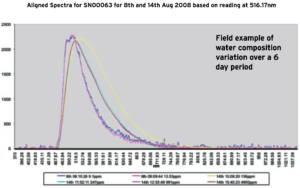

Aligned Spectra for SN00063 for 8th and 14th August 2008 based on reading at 516.17nm.

Interface example

Recent analysis at Talisman Flotta Terminal.

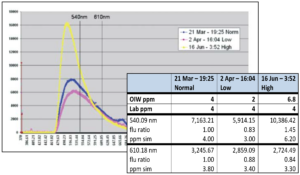

Chemical Interface

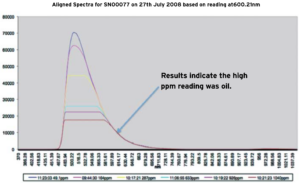

Evaluating water composition. Concern that high ppm (>100ppm) was a process chemical effect.

Aligned Spectra for SN00077 on27th July 2008 based on reading at 600.21nm.

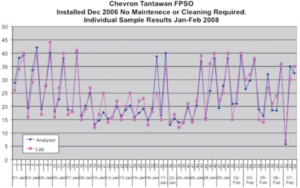

Chevron Tantawan

Chevron Tantawan FPSO

Installed December 2006 – No Maintenance or Cleaning Required.

Individual Sample Results, January – February 2008.

Measurement Principles

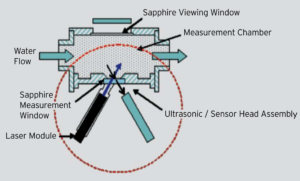

- The measurement technique incorporated in the Advanced Sensor’s monitors is laser-induced fluorescence.

- Ultraviolet Optical Fluorescence is used to measure oil content. Fluorescence is the preferred method for measuring low oil levels (0 to 1,000 ppm).

- The transducer sensor head is a combined optical and ultrasonic component. The laser passes through a smaller sapphire window to excite the water sample, while the fluorescent properties are captured via optical fiber light guides and taken to:

- An optical filter and photo multiplier tube (PMT). The optical filter selected depends on the wavelength properties in the water.

- An optical UV spectrometer (for the EX1000).

Measurement Technique

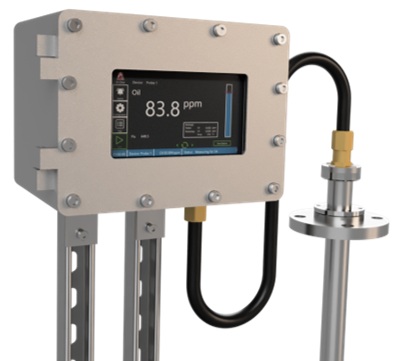

Advanced Sensors’ OiW

Advanced Sensors’ Oil-in-Water Monitor

Lessons Learned

The new monitors:

- Have proven more accurate in detecting OiW in upstream produced water and downstream

- wastewater streams.

- Provide accurate OiW concentrations in disposal water and may be used to monitor

- flotation unit efficiency since they may detect up to 2% oil.

- Are maintenance-free and correlate concentrations well with grab samples due to the

- ultrasonic cleaning feature of these monitors.

- Save labor amounts and chemicals used to extract oil from water during implementation.

Best Practices

The new monitors:

- Have proven to increase measurement accuracy and reduce operator maintenance.

- Determine product loss via reinjection or surface discharge.

- Track the efficiency of water treatment systems to enhance oil recovery and revenues and reduce liability of environmental discharges.

Installation

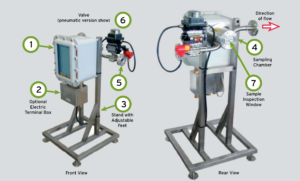

Installation on Benchamas Production Platform

Sampling Chamber

Advanced Sensors’ Sampling Chamber

Conclusions

- The EX-100 installed on Tantawan Explorer has been performing well.

- There is excellent agreement with grab samples – SX with Wilks IR and hexane gravimetry.

- The operators love “maintenance free” monitor.

- The unit installed on Benchamas Explorer performs well after being upgraded to EX-1000, because the interference from the demulsifier was eliminated.

- The EX-1000 installed on Benchamas processing platform has been performing well, but the parameter should be adjusted to get better agreement with the laboratory result.

- Advanced Sensor’s OIW monitors reduce lab technician time and solvent use/exposure.

- Advanced Sensor’s OIW monitors provide an immediate alarm to control rooms when the water treatment system is upset.

Authors:

Darrell L. Gallup | ETC

Papon Thanomkiat | CGUG

Surachai Pongsuthana | CGUG