GCxGC Isn’t Just a Tool for Research

How ASTM D8396 is shaping the future of compositional characterization in synthetic aviation fuels (SAF).

Rethinking Traditional Hydrocarbon Analysis

Credit: Lukasz Katlewa, Gdańsk University of Technology, Poland.

When thinking about hydrocarbon analysis, it is natural to think of gas chromatography (GC). However, simple GC (single column) separation doesn’t always provide the complete answer. When full separation is impossible due to complexity of the mixture and functionality of a simple column system, other options can be considered, such as a different detection type or more complex chromatography.

In the past, many avoided complex chromatography because of a limited understanding. However, in recent times, it is becoming more widely accepted due to benefits like simplicity of sampling and speed of analysis.

What Is GCxGC and How Does It Work?

Two-dimensional gas chromatography (GCxGC) is a multi-step separation that happens within a single GC instrument using a modulator in between two columns. A sample is injected into a system and passes through a first column to perform an initial separation grouping compounds together based on the column selected.

The grouped compounds then enter a modulator that is used to hold the groups before sending them onto the second column. This column then performs a secondary separation. The modulator comes in one of two styles: flow or thermal. In flow modulation, we use the direction of the carrier gas flow as a trapping and releasing mechanism whereas thermal modulation uses temperature.

In both cases, two different phase columns are used to achieve better separation and resolution of the complex sample. The selection of these two columns gives users the ability to determine how the grouping/pre-separation and secondary separation happen. For example, you may want to group samples on the first column based on their polarity and use the second column separate on boiling points allowing for the identification of compounds that may experience coelution problems.

From Research to Routine: The Expanding Role of GCxGC

Though two-dimensional separation is nothing new, it has mostly been utilized by those who are doing research. Here, users have time for finetuning methodology and exploration into the column selection to achieve the separation being sought after. Also in research, there are not always starting methods that need to be followed when looking for answers. For those in industries like Oil and Gas, however, there is little room for exploration or working outside of standardized methods. Adoption of more complex techniques takes time to become accepted by the industry as a whole; though, that is exactly what is happening in ASTM.

Why GCxGC Matters for Synthetic Aviation Fuel (SAF)

A major challenge in that marketplace is finding better ways of performing compositional characterization of petroleum products that can be implemented routinely in the lab and provide additional insight into complex samples. Synthetic aviation fuel (SAF) is an example of the type of sample. SAF is generated from different renewable sources through one of eight approved pathways, like HEFA (hydro-processed esters and fatty acids) fuels being generated from recycled oils. As each of the starting points and pathways are different, the final product contains different compositional amounts of compounds like paraffins, naphthenes and aromatics. These synthetic fuels can be blended with traditional jet fuel (which has known and tightly controlled specifications), so understanding the characteristics is critical to making the final blends perform as expected.

ASTM D8396: A New Standard for GCxGC in Hydrocarbon Analysis

Within the current ASTM D02 committee for Petroleum Products, Liquid Fuels, and Lubricants, SAF producers need to follow the guidelines found in D7566 (Standard Specification for Aviation Turbine Fuel Containing Synthesized Hydrocarbons) that list the characteristics of the final SAF based on the pathway used. In most instances, the primary method for determining composition is D2425 (Standard Test Method for Hydrocarbon Types in Middle Distillates by Mass Spectrometry). This standard utilizes GC-MS but requires a pre-separation of the sample into the saturate and aromatic fractions prior to injection and can take days to complete.

In 2022, a new method utilizing GCxGC, D8396 (Standard Test Method for Group Types Quantification of Hydrocarbons in Hydrocarbon Liquids with a Boiling Point between 36 ℃ and 343 ℃ by Flow Modulated GCxGC-FID) was approved.

To be approved, a pilot study needed to be run. During that study, 22 labs participated and 17 of them tested SAF samples. There was a variety in both the experience level of the operators as well as the type of labs that participated, including both research and routine. From a sample perspective, seven different SAF samples were able to be analyzed to better understand how D8396 could be used in the future to update the current guidelines for testing.

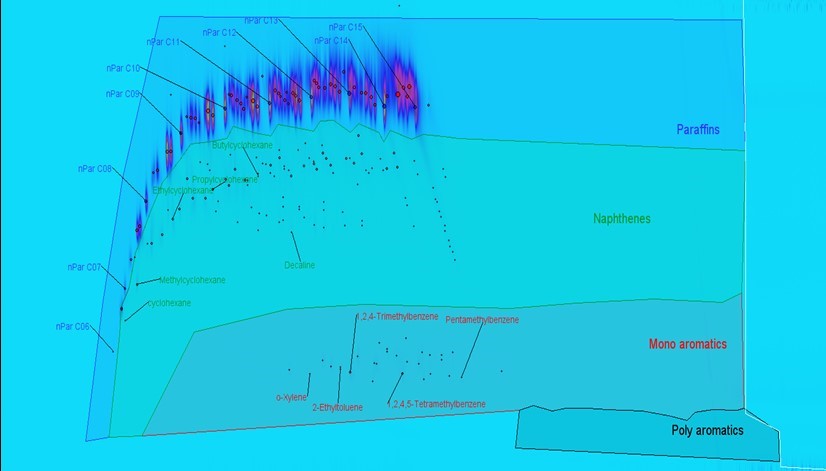

An example of the HEFA sample can be seen in Figure 1.

Figure 1: Example of HEFA sample using GCxGC-FID by method D8396. Individual compounds are identified with sections for specific groups of compounds outlined on the right.

The Future of Hydrocarbon Characterization

The original and future goal for the method is to keep it as open as possible to allow for flexibility within the lab; however, based on the initial study and what was learned, additional guidelines may be added. This method was created to focus on petroleum products like SAF and has shown success within industry labs, despite the technique being thought of by many as only used for research. The voluntary participation by many laboratories during a pilot study also indicates a shift in how users view GCxGC as changes in sample complexity continues. The story of this method isn’t finished, the group within ASTM is continuing to work on the next steps which is an interlaboratory study with the goal of being listed as a test method within the larger D7566 guidelines.

While it isn’t the first GCxGC ASTM method, D8396 has gained significant interest within the liquid fuels space. The industry overall is looking to complex and alternatives techniques. As the landscape of complex products and the need for deeper understanding of compositional analysis grow, advanced techniques like GCxGC will move from being thought of as only for academics and become more accepted amongst users for more routine use.

About the Author: Nicole Lock is the Group Product Manager for Chemical and Atomic Analysis at PAC and a member of the LabCompare Editorial Advisory Board. Nicole graduated from Seton Hill University with a Bachelor of Science in Chemistry. She started her career as a service engineer in a small third-party service organization repairing multiple brands’ GC and GCMS units. This skill set led Nicole to the analytical instrument industry where she has spent the last 18 years working in both the service and marketing department representing the GC and GCMS product lines. Her passion is helping new customers find answers to their unknown problems and current customers make the most of the systems they use every day.