Distillation Processes: A Comprehensive Guide to Physical Distillation Techniques

Petroleum is a complex mixture of organic materials called crude oil and natural gas, which occurs naturally in the ground and was formed millions of years ago. Crude oil and natural gas are of little use in their raw state; their value lies in what is created from them: fuels, lubricating oils, waxes, asphalt, petrochemicals and pipeline quality natural gas. A suitable process is required to separate these useful products from the petroleum. Of course, distillation is the commonly employed process for petroleum separation.

Key Distillation Techniques in Petroleum Processing

Various distillation techniques are then necessary to characterize each of these products, not only for their end usage but also for information during the separation process. We can categorize these techniques in the following fashion: Crude oil distillation, Atmospheric distillation, Vacuum distillation. Each of these categories have alternate techniques which can provide similar characterization information and utilize more economical means such as simulated distillation, microdistillation, or spectroscopy.

Crude oil distillation provides the boiling point characteristics of a batch of the crude petroleum that is intended for separation in a refinery. This yields information on the volume of particular components that can then ultimately be used for producing the final products such as gasoline or diesel. The crude oil distillation analysis can cover all stages of the process from recovering light gases, atmospheric stage liquids such as naphthas, vacuum stage liquids that are higher boiling temperature liquids that can then be converted by cracking to usable products, and residual material that might be used for asphalt or petrochemicals.

Atmospheric distillation provides the boiling point distribution of the lighter liquids during the refining process to monitor whether it will meet the final specifications for the intended product usage and then also is the means for the final quality check before certification to specification and release of the product to the market. It is the most frequent distillation undertaken by laboratories and online process monitors.

Vacuum distillation generally is utilized for characterizing the residual material composition that remains after a particular stage in the refining process. Since the first stage or atmospheric distillation separates the lighter boiling components, the residual material will need a reduced pressure distillation to avoid thermal decomposition of the material. This characterization then allows the next process stage to be prepared appropriately or might be used when transferring the material to another facility for additional applications such as petrochemical.

Simulated distillation, sometimes known as SIMDIS, is a gas chromatographic technique that has been correlated to the characterization of boiling points of various sample types could also be utilized in all the process stages, as well as in quality control and in the final certification for meeting product specifications. SIMDIS correlations have been developed for all stages of the petroleum refinery process including light gases, liquified petroleum gas (LPG), motor fuels, aviation fuels, along with correlations for crude oil distillation and high boiling temperature vacuum stages. SIMDIS can provide efficient information on distillation characterization in a shorter time and less sample volume than traditional distillation test methods.

Micro Distillation can be viewed as a miniature atmospheric distillation technique that provides an economical approach when assessing fuels during process, quality control, and final certification. Using a micro size sample and a test duration one third that of traditional distillation, micro distillation has shown application to motor fuels, aviation fuels, and even 100% biodiesel.

Spectroscopy by FTIR-ATR techniques are also employed in characterization of fuels once spectroscopic models have been developed for the fuel types involved. FTIR analysis generally is applied on the finished or certified fuels where it is a convenient mobile means to assess the boiling points of gasolines and diesels as to whether they are within specification limits. FTIR analyzers are also employed during process control of refinery for real time analysis of process streams.

Standardization and Industry Applications

Atmospheric distillation was one of the earliest standardized test methods; ASTM D86 Standard Test Method for Distillation of Petroleum products at Atmospheric Pressure was first approved in 1921 as a tentative method. As fuel compositions have evolved over time the scope of D86 has also evolved to include additional fuel types such as blends with ethanol or biodiesel. D86 remains one of the most utilized test methods in the industry. About 50 years later in the 1970s, automated apparatus versions of D86 were introduced, eventually standardized into the existing distillation test methods and which are now the preferred apparatus utilized providing welcome relief to testing laboratory operations. Several adaptations on D86 have occurred providing application to materials other than petroleum products, such as ASTM D850 Standard Test Method for Distillation of Industrial Aromatic Hydrocarbons and Related Materials, D1078 Standard Test Method for Distillation Range of Volatile Organic Liquids, and these adaptations have also incorporated the automated apparatus into their standardized test methods.

The alternate techniques for physical distillation have generally maintained pace with the expansion of scopes to include additional fuel types as they become prevalent in the market.

Vacuum distillation or reduced pressure distillation was introduced not many years later after it was realized that eventually petroleum would decompose and become unusable due to the high temperatures needed in atmospheric distillation. Physically reducing the pressure in a system allows the liquid to boil at lower temperature and more petroleum fractions can be separated. Even more approaches for converting petroleum over to lighter fractions, such as catalytic cracking, were eventually introduced to utilize even more of the petroleum yield. Test methods for reduced pressure distillation continue to provide the information for operation of these processes. Like atmospheric distillation test methods, vacuum distillation test methods have introduced automated apparatus as well as alternate test technology such as High Temperature SIMDIS.

Distillation Methods Summarized:

Example:

| Method | Brief Summary | When to choose this method? | Global Method Equivalency |

| ASTM D86 IP 123 ISO 3405 DIN 51751 JIS K2254 |

Atmospheric distillation method most often used test in daily process, quality control, and certification for fuel specification. | Common use is refinery process naptha/alkylate/etc. streams, engine fuel quality control and certification for gasolines, diesels, heating oils, kerosines, jet fuels. | All global methods harmonized to maintain consistency. |

| ASTM D850 | Atmospheric distillation method most often used for quality and purity assessment of aromatic liquids. | Common use in chemical or petrochemical process producing toluenes, benzenes, and Xylenes | |

| ASTM D1078 IP 195 |

Atmospheric distillation method most often used for quality and purity assessment of organic solvents. | Common use in chemical or petrochemical process producing solvents for chemical processes such as alcohols, glycols and ketones. | All global methods harmonized to maintain consistency |

| ASTM D1160 | Characterization of residual material from atmospheric or vacuum processing in refinery | Common use is for characterization of atmospheric or vacuum tower bottoms prior to use as feedstock in additional conversion processes. | |

| ASTM D2892 | Crude Oil assay characterization provides lab scale simulation information of full scale refinery processing | Crude oil characterization of refinery feedstock | |

| ASTM D5236 | Crude oil residual material characterization on lab scale provides information of full scale refinery processing of heavy residuals | Refinery process residual material characterization for further refinery processing or transfer to external party. | |

| ASTM D7345 EN 17306 |

Measures liquid temperature, vapor temperature and differential pressure during the entire physical distillation process in a specially designed flask. | Choose when you need significantly faster results compared to the conventional ASTM D86 method. | Correlates to ASTM D86. EN version is equivalent. |

| ASTM D2887 | SIMDIS is a GC compositional analysis correlated to D86, D1160 or D2892 | Choose when you need significantly faster results compared to the conventional ASTM method. | |

| FTIR-ATR | SpectroscopIc analysis either online or portable provides modeled correlation to atmospheric distillation | Choose when you need significantly faster results compared to the conventional ASTM D86 method. |

PAC leads in the standardization community in continuous improvement of distillation test methods to keep pace with evolving fuel types. We currently lead the task group on developing alternate temperature verification procedures to replace the toxic mercury containing thermometers. We lead projects in international standards groups for maintaining alignment amongst the distillation test methods. Michael Collier who is chair of the ISO International Standardization Organization on Petroleum and Related Products, is also the chair and project leader for the ISO distillation test methods.

Featured Products

OptiDist 2

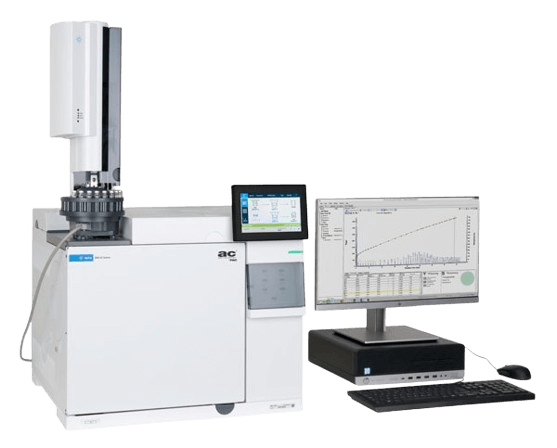

SIMDIS Analyzer