Determination of Total Sulfur in Light Hydrocarbons by UVF according to ASTM D5453

The ElemeNtS analyzer offers rapid and accurate determination of chemically bound sulfur, a fully automated injection and combustion system, and excellent sensitivity, repeatability, and linearity.

Introduction

Sulfur is a natural present element in most hydrocarbon feed streams and responsible for many undesirable effects like catalyst poisoning, detrimental product quality and ecosystem pollution. So there is a need to quantify and monitor the sulfur content in nearly every step of the industry’s operations, or for final product specification or regulatory control.

Total analysis of the Sulfur content in hydrocarbons by combustion and UV fluorescence detection has been established as the preferred method to characterize feedstock, intermediate streams and finished hydrocarbon products due to its sensitivity, linearity, dynamic range and ruggedness.

ASTM D5453 is an established test method for the determination of total sulfur in liquid hydrocarbons containing 1.0 to 8000 mg/kg total Sulfur, boiling in the range from approximately 25°C to 400°C and with viscosities between approximately 0.2 and 20 cSt (mm 2 / at room temperature. This test method is applicable to the determination of total sulfur in liquid hydrocarbons containing less than 0 35 % (m/m) halogen(s).

Measuring Principle

A hydrocarbon liquid sample is directly injected, by a fully automated liquid sampler, into a high temperature, dual temperature zone combustion tube where the sulfur components are vaporized and combusted. The released sulfur is oxidized to sulfur dioxide (SO2) in an oxygen rich atmosphere.

![]()

A stream of inert gas (helium or argon) takes the reaction products, after removal of the produced water vapor, into a reaction chamber. Here, the SO2 molecules are converted to excited SO2* by the absorption of energy of a UV lamp and emitting light (fluorescence) while it relaxes to a stable state.

A Photomultiplier tube measures the emitted light signal.

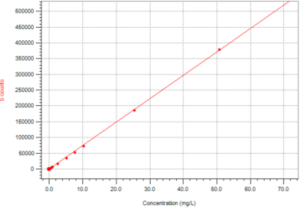

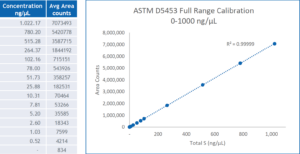

The response signal is integrated to calculate the area. The sulfur concentration of an unknown product is calculated using the linear regression function of the concentration of standard mixtures versus integrated area.

Linear regression function

Validation

The system and methodology of the Antek ElemeNtS total sulfur analyzer is thoroughly tested for response linearity, sample scope, recovery, and repeatability to validate its performance according to ASTM D5453.

Calibration

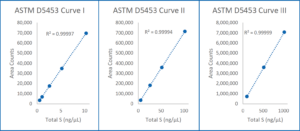

Calibration curves are composed using tert-Butyl-di-Sulfide in o-Xylene standards. Each calibration solution and blank (o-Xylene) is measured three times. The average response of the blank injections is subtracted from each calibration standard response conform method. Although the ElemeNtS system is linear in response in the range from 0 – 1000 ng/µL (figure 1), separate calibration curves have been created according to the suggested ranges in ASTM D5453 (Figure 2,3,4).

Table 1: Response values.

Figure 1: Full range calibration curve covering typical range of ASTM D5453

Figure 2: Curve I (0,5-10 ng/µL)

Figure 3: Curve II (5-100 ng/µL)

Figure 4: Curve III (100-1000 ng/µL)

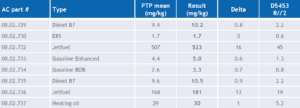

Sample Scope

Different types of samples were selected to cover the boiling point range of the scope of the method (Gasoline BOB, Reformulated Gasoline, E85, Diesel B7, Jet fuel, heating oil). To obtain one result, each sample is measured three times, and the average detector response is calculated. The results are compared with the consensus values obtained during a Proficiency Testing Program (PTP). All sample results are within the ASTM D5453 reproducibility limits (Table 2).

Table 2: Overview of sample results, compared with consensus values of PTP.

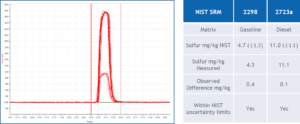

Recovery / Bias

Two NIST standard reference materials (SRM) were analyzed to determine the bias such as described in ASTM D5453-16, chapter 15.2. The samples were gasoline SRM 2298 (4,7 mg/kg ± 1,3 mg/kg), and diesel SRM 2723a (11,0 mg/kg ± 1,1 mg/kg). The observed differences between the determined values and the ARV (Accepted Reference Values) of the NIST standards are well within the NIST uncertainty limits (Table 3). A representation of the injection signal of NIST SRM 2298 and 2723a can be observed in Figure 5.

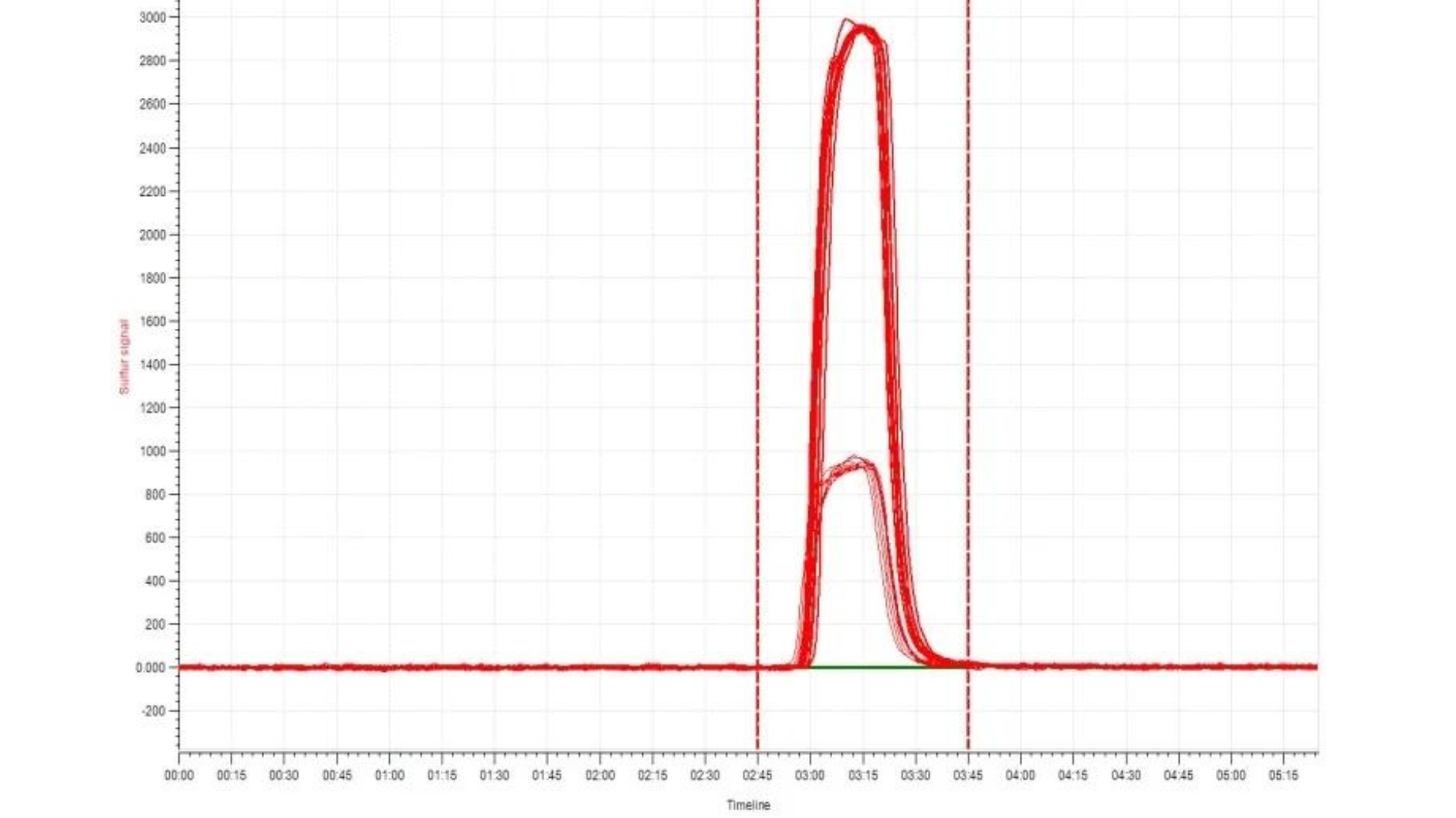

Figure 5: Overlay NIST SRM 2298 and SRM 2723a signal (n=10)

Table 3: Comparison of NIST and analysis results.

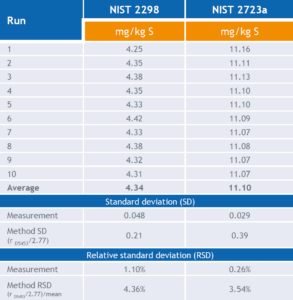

Repeatability

Area is the primary measurement in total sulfur analysis. The precision in which it is measured ultimately determines the validity of the generated quantitative data. Area precision requires that all operational conditions are precisely controlled. Furthermore, the inertness of the flow path can considerably affect area precision, especially for sulfur components at low levels.

Concentration repeatability for the ElemeNtS total sulfur analyzer is measured for 10 consecutive runs on two NIST reference samples. Repeatability standard deviation of Total sulfur is well within the precision statement of ASTM D5453.

Table 4: Repeatability values of NIST 2298 and 2723a reference material

Conclusion

These results demonstrate that the ElemeNtS analyzer is a powerful tool for the determination of sulfur in Light Hydrocarbons, Spark Ignition Engine Fuel, Diesel Engine Fuel, and Engine oil, based on the exceptional calibration linearity, low limit of detection, excellent repeatability and recovery.

The Antek ElemeNtS Total Sulfur analyzer is meeting the ASTM D5453 requirements.

PAC powered by Antek’s lab instruments provide reliable, precise elemental analysis for total nitrogen and sulfur and speciated nitrogen and sulfur. Antek products are recognized by global regulating bodies, leading scientific research institutions, and process laboratories as the instrument of choice for selective multi-element detection.

Featured Products

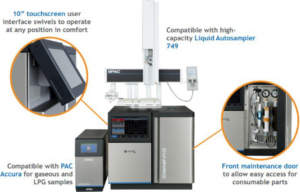

Elements