Enhancing Fuel Quality with Gas Chromatography

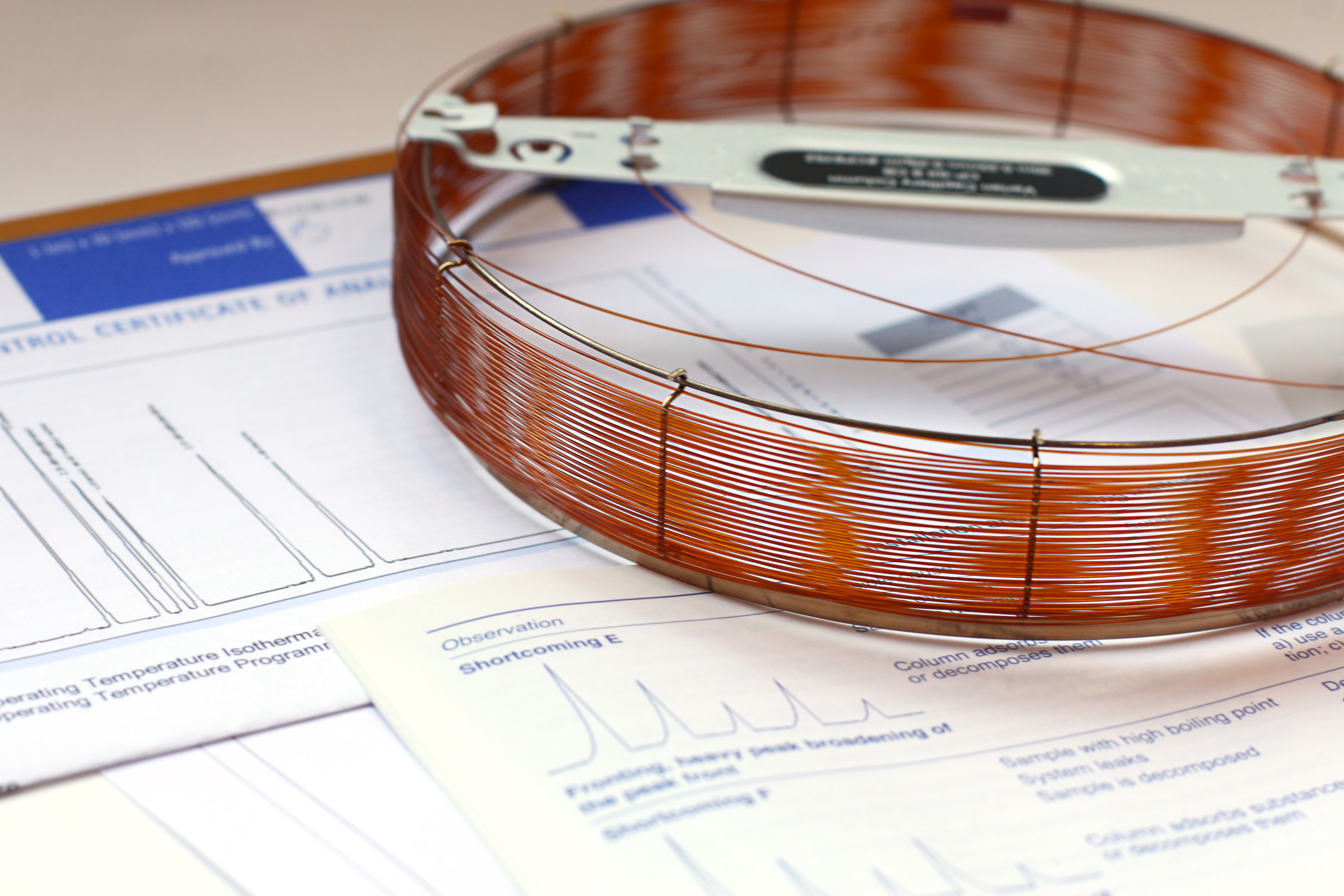

Gas chromatography (GC) is a vital tool for separating and analyzing compounds that can be vaporized without decomposition.

In gas chromatography, two primary approaches are employed: targeted and non-targeted analysis. Targeted analysis focuses on detecting and quantifying specific, known compounds within a sample, relying on pre-established knowledge of the analytes of interest. This method is highly sensitive and precise, making it ideal for applications where specific contaminants or compounds need to be monitored. In contrast, non-targeted analysis aims to comprehensively profile all detectable compounds within a sample, without prior knowledge of what those compounds might be. This approach is invaluable for exploratory studies, unknown compound identification, and comprehensive profiling of unknown mixtures, providing a broad overview of the chemical composition of a sample. Together, these two approaches enhance the versatility and scope of gas chromatography, catering to a wide range of analytical needs.

Targeted Analysis in the Oil and Gas Industry

Targeted analysis involves the identification and quantification of specific, known compounds or parameters in a sample. This approach ensures that fuels meet stringent quality and regulatory standards by measuring predefined compounds or properties. While GC is key to these types of analyses, there are additional techniques that can be in conjunction to provide a more holistic understanding of the samples.

Gas chromatography uses targeted analysis to separate and analyze volatile components in fuels with high precision. High-performance liquid chromatography (HPLC) complements gas chromatography by effectively separating and quantifying less volatile and thermally unstable compounds. Mass spectrometry (MS) is often coupled with GC or HPLC, resulting in GC-MS or LC-MS, to achieve precise identification and quantification of chemical species.

Another essential technique is Fourier transform infrared spectroscopy (FTIR), which identifies functional groups and verifies chemical composition. Atomic absorption spectroscopy (AAS) is employed to detect metal contaminants in fuels, ensuring safety and compliance with standards. X-ray fluorescence (XRF) determines sulfur content and other elemental compositions, which are critical for both environmental and regulatory reasons. Additionally, measuring the octane number for gasoline and the cetane number for diesel is vital for assessing combustion quality and ensuring efficient engine performance.

Targeted analysis measures several key parameters, such as sulfur content, which is essential for regulatory compliance and minimizing environmental impact. The levels of benzene, toluene, and xylene (BTX) are monitored to assess the presence of hazardous aromatic hydrocarbons. Polycyclic aromatic hydrocarbons (PAHs) are also tracked due to their carcinogenic properties. Metals like lead and manganese are analyzed to prevent engine wear and meet safety standards. Furthermore, additives such as detergents and antioxidants are scrutinized to ensure optimal fuel performance and stability.

By leveraging these advanced analytical techniques, the oil and gas industry can maintain high standards of fuel quality and safety, meeting both regulatory requirements and consumer expectations.

Non-Targeted Analysis in the Oil and Gas Industry

Non-targeted analysis is a comprehensive approach that examines all detectable compounds in a sample without prior knowledge of what compounds to expect. This method is essential for identifying unknown contaminants, discovering new compounds, and monitoring for unexpected changes in fuel composition.

Gas chromatography-mass spectrometry (GC-MS) is commonly used in non-targeted analysis for detecting a wide range of volatile and semi-volatile organic compounds. Liquid chromatography-mass spectrometry (LC-MS) is employed for non-volatile and thermally labile compounds, providing a broad detection range. Fourier transform ion cyclotron resonance mass spectrometry (FT-ICR MS) offers high-resolution mass spectrometry to identify complex mixtures of compounds, making it a powerful tool for non-targeted analysis.

Nuclear magnetic resonance (NMR) spectroscopy is another critical technique used for structural elucidation of unknown compounds, aiding in the identification and characterization of new substances. Comprehensive two-dimensional gas chromatography (GC×GC) enhances the separation and analysis of complex mixtures with higher resolution, allowing for a more detailed examination of fuel samples.

Non-targeted analysis has several key applications in the oil and gas industry. It is used for screening unknown contaminants, which is vital for ensuring fuel safety and quality. Profiling fuel composition changes over time or due to different processing conditions helps in understanding the stability and performance of fuels. Investigating fuel degradation products is crucial for assessing the longevity and reliability of fuels under various conditions. Additionally, discovering new additives or contaminants introduced through raw materials or manufacturing processes can lead to innovations and improvements in fuel formulations.

Comprehensive Analytical Strategies for High-Quality Fuel

Targeted analysis is precise and specific, focusing on known compounds and properties to ensure compliance and quality, making it routine for regulatory compliance and meeting product specifications. In contrast, non-targeted analysis provides a broader overview, enabling the detection of unexpected or unknown compounds. This approach is valuable for research, quality control, and troubleshooting, helping to identify new issues or changes in fuel composition. Together, these analytical methods offer a comprehensive strategy for maintaining high standards in the oil and gas industry.

Both approaches are complementary and critical for maintaining high fuel quality standards in a refinery laboratory.

Featured Products

Customized GC

SeNSe²