Thermal Oil Recovery

Thermal oil recovery is anything that uses steam to enhance oil recovery, or to recover hydrocarbons that are below the ground. This is common, for example, in heavy oils sands production.

Introduction

In this process, steam is forced under pressure into the reservoir through a pipeline. The steam acts to break loose the heavy oil from the formation where it drains into another line. This resultant emulsion of hydrocarbons and water is recovered through this second line that carries it to the surface for treatment. The emulsion then enters a primary separation train, where a Free Water Knockout (FWKO) separator provides bulk separation of oil and water. The oil is recovered and sent for further processing and the residual water, which contains trace levels of hydrocarbons and other contaminates, is sent to a produced water treatment train to be polished and recycled for steam generation.

Steam and water are the critical components in this process, and it’s necessary to recycle as much of the water as possible. Thermal oil recovery requires massive amounts of water, and it’s not feasible or environmentally responsible to source water from a river or lake. For every barrel of oil captured, it takes nine or more barrels of water, which contains trace levels of hydrocarbons and other contaminates, to complete that effort. In order to maintain the process, the water needs to be treated and recycled.

After primary recovery of the oil in the FWKO, water from thermal recovery goes into a large skim tank for further oil recovery. From there, the water is often sent to an induced gas flotation (IGF) unit, which forces gas into the water phase, creating bubbles that attach to oil droplets that are still in the water. This changes the apparent density of the oil droplets, causing them to rise or “float” to the surface more rapidly than they would otherwise. Oil is skimmed off from the surface of IGF and the water is typically sent to a nut shell filter (NSF), or another type of oil reducing filter (ORF). Any remaining oil is filtered out and the resulting clean water flows to pretreatment for steam generation, typically softening or distillation. After removal of suspended and dissolved solids, the water is sent to the boiler.

Challenge

It’s important to have extremely clean water in steam generation. If residual oil in the water gets into the pretreatment equipment, it will lead to production shutdown. Depending on the number of barrels of oil per day that are being produced, this can be a tremendous financial impact. For every 10k barrels, it’s a $700,000 per day financial impact. Even if the evaporator is back up and running in six hours, that is still a loss of 25% on a unit that runs for 24 hours a day.

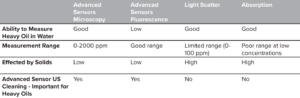

In the past, several methods have been used to detect oil in water, and none of them are especially reliable. Fluorescence, for example, has a good range and isn’t affected by solids, but it isn’t great at measuring very heavy oil in water. Unfortunately, in SAGD operations, the chemicals used in the process fluoresce more than the oil, making fluorescence virtually useless.

The light scatter and the absorption methods are both effective at measuring heavy oil in water. However, they have a limited range and are negatively affected by the amount of solids in the water. Additionally, neither instrument is self-cleaning.

Solution

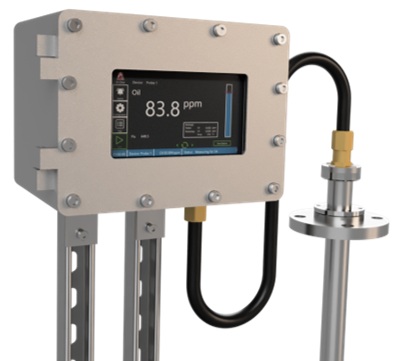

The industry needed a solution that could measure this heavy, sticky oil in water, which had a wide measurement range, and that was unfazed by solids in the water. To solve the problem, Advanced Sensors used our EX-400 Side Stream Analyzer, based on microscopy, to take continuous video with a digital microscope. Using human algorithms and machine learning, the EX-400 is able to distinguish between oil droplets and solid particles. What’s more, the EX-400 is self-cleaning.

The EX-400 is the first analyzer to really work effectively in an online, continuous basis. Microscopy is capable of detection—including telling the difference between solids and oil—where other technologies fall short.

EX-400 Benefits:

- Easy to use, with no routine maintenance

- Measures and distinguishes between measure oil and solids

- Low total cost of ownership

- No degradation of signal or recalibration required

- Localized sample control

- Remote control and monitoring (suitable for un-manned locations and remote process monitoring)

EX-400 Analyser

Point-in-time sampling methods (e.g. lab measurement) can be applied, but these are likely to give the wrong impression of what is occurring in the produced water and likely to miss costly upsets. With the EX-400, several images are taking every second and continuous result are supplied, providing the customers with the insight to optimize the process, and never miss upsets, while saving vast amount of time when compared to sampling and waiting for results.

Comparison of Solutions

Table 1: Thermal Oil Recovery