State-of-the-Art Solution

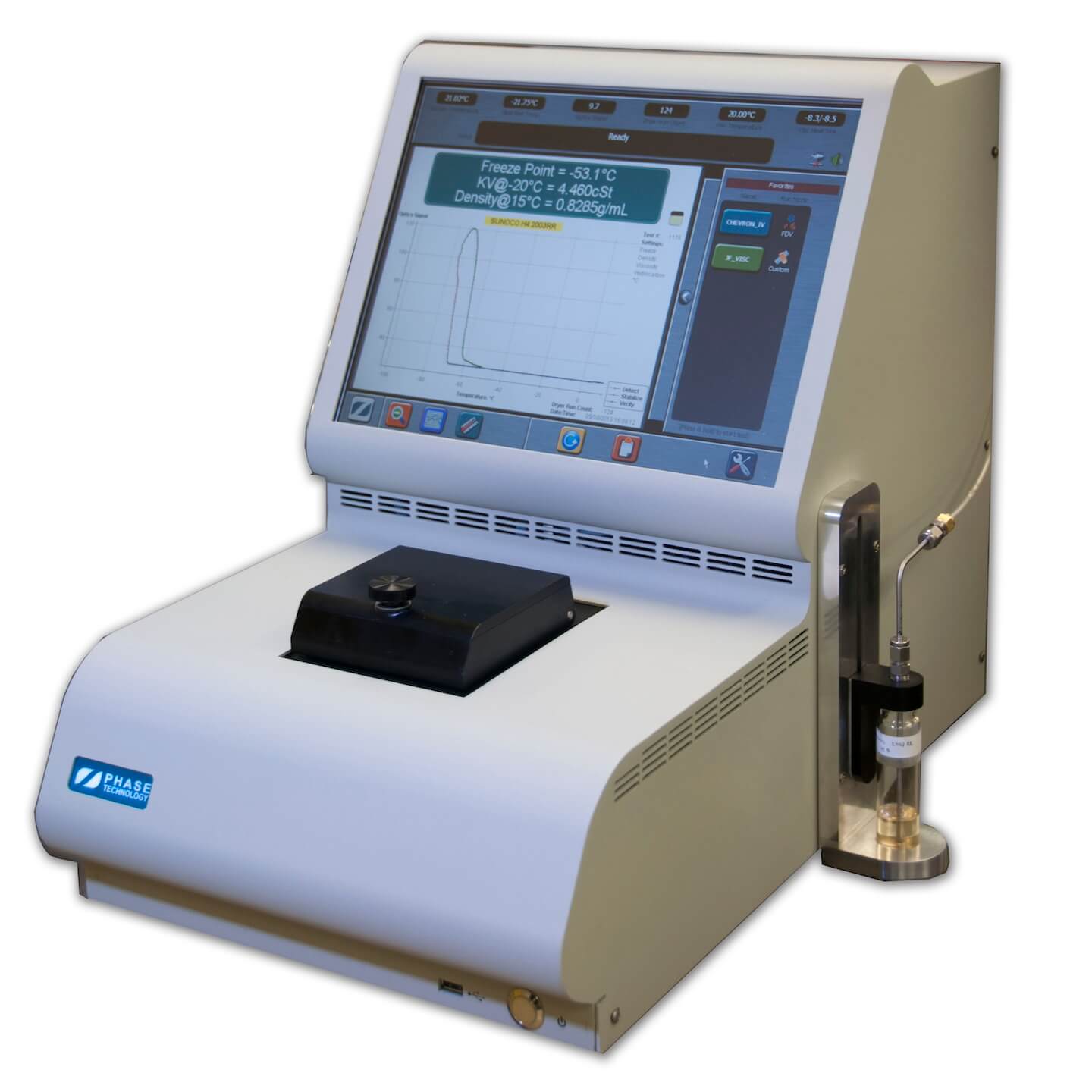

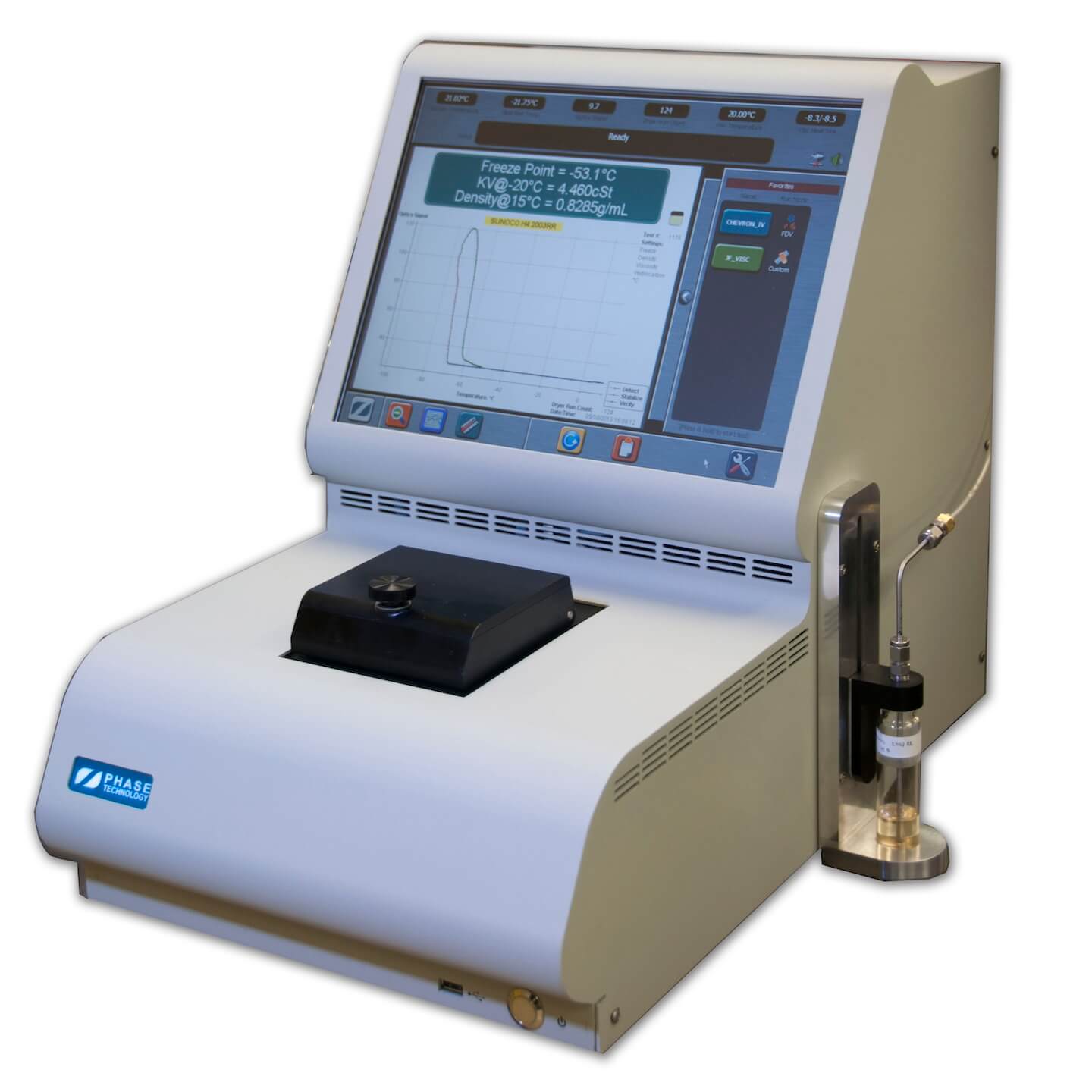

PAC Powered by Phase Technology’s JFA-70Xi jet fuel analyzer is the world’s first instrument that performs three crucial tests in one unit—freeze point, viscosity and density. And, it does it all in less than 15 minutes!

Product Overview

Phase Technology’s JFA-70Xi jet fuel analyzer is the world’s first instrument that performs three crucial tests in one unit—freeze point, viscosity and density. And, it does it all in less than 15 minutes!

The JFA is also available as a 5-in-1 analyzer, adding cloud and pour point for diesel fuel. That makes it the most versatile analyzer in your lab!

The JFA-70Xi features a side loaded automatic sample injection port. There’s no longer a need to manually pipette. The analyzer always draws the precise amount of sample as required by the ASTM method.

The JFA-70Xi is completely self-cleaning, without the need of solvents. Save time and hassle of cleaning, and avoid any risk of damage to the sample cup.

With the superior advantage of JFA-70Xi’s ASTM D5972/IP 435 automatic freezing point method to detect low levels of incidental materials and other contaminants, in addition to being an approved method for standard Jet A and Jet A1, it is currently the referee method when SAF is co-processed

to ensure that the freezing point will not be negatively impacted by levels of unconverted raw materials.

With an unsurpassed precision, JFA-70Xi’s ASTM D7945 method is an approved viscosity test method in all of ASTM D1655, ASTM D7566 and Def Stan 91-091 global jet fuel specifications for testing viscosity at both -20°C and -40°C.

The JFA-70Xi is also available with a 48-station autosampler, which allows unattended testing. Users can initiate 1 to 48 runs in a row, then walk away and let the analyzer do the rest.

Key Features

Super fast speed

Advanced viscosity capability

Approved for jet fuel certification

Automatic sample input – No pipette required.

Self cleaning – no solvent required.

No external chiller – Quiet, cool, self-contained thermoelectric cooler

No breakable glassware with internal capillary system

Superior precision with best measured repeatability and reproducibility

Specs

Test Methods & Precision

Standard Test Methods:

Freeze Point: ASTM D5972 (IP 435), SH/T 0770-2015, GOST 52332, ASTM D2386 (IP 16/ISO 3013) equivalent or better

Kinematic Viscosity: ASTM D7945 @ -20°C, @ -40°C and @ 12cSt, ASTM D445 (IP 71/ISO 3104) equivalent or better

Density: ASTM D7777, ASTM D4052 (IP 365/ISO 12185) @ 15°C correlation

Repeatability & Reproducibility:

Freezing Point: Repeatability: 0.5 ºC Reproducibility: 0.8 ºC

Kinematic Viscosity:

Repeatability: 0.011cSt @ -20°C, 0.021cSt @ -20°C, 0.0018 X1.4 cSt @ -40°C, 0.0021 X1.4 cSt @ -40°C

Reproducibility: 0.021cSt @ -20°C, 0.0021 X1.4 cSt @ -40°C, 0.17°C @ 12cSt

Density:

Repeatability: 0.006081 (1000 – x) kg/m3

Reproducibility: 0.008545 (1000 – x) kg/m3

Bias: 0 (relative to ASTM manual methods)

Operation

Detection: Diffusive Light Scattering (DLS) technology for freeze point. Horizontal capillary with motive force for viscosity

Cooling System: Integrated Peltier device cooling system Linear cooling profiles according to freeze point test method

System Cleaning: Automatic flush cycle, no solvent required

Application Range

Freeze Point Temperature Range: Sample: – 80 to +70°C °C or °F (user selectable)

Test Resolution: 0.1°C

Measurements

Sample Size: 0.15 mL required for test minimum, 20 mL including cleaning

Test Duration: Freeze Point & Density combined: 8 to 10 minutes Viscosity & Density combined: 10 minutes Freeze, Viscosity & Density combined: 15 minutes

Required Operator Time : 0.25 minutes

Documentation

Printing Label printer: Detailed test report in °C or °F with date & time stamped, sample information, test mode

Full-size printer: Detailed detection curve tracking of fuel behaviors during the test; can be printed as part of test report.

Internal Memory: Storage up to 5000 test runs

QC-Functions: Automatic QC-sample handling and QC-Chart

Interface

Display: Full-color, touch-sensitive, 15” high-resolution LCD screen with virtual keyboard. Languages: English, Chinese

Printer: USB interface for label printer or full-size HP/PCL printer

LIMS interface: Ethernet or RS232, Automatic LIMS transfer

Data Export: USB Memory Stick, Import into Excel

Password Protection: Different access levels for Operator, Manager, Service

Diagnostics: Automatic diagnostic functions

Accessories: Barcode Reader, label printer

Utility Requirements

Electrical: 90V to 260 VAC; 47-63Hz; 350W

Ambient Conditions: Temperature: max. 10° to 30°C; extremes not recommended

Dimensions: 54.6 cm (21.5”) deep x 33.7 cm (13.25”) wide x 44.5 cm (17.5”) high

Weight Unit: 24 kg (53 lb.) Boxed: 28 kg (62 lb.)